Job Safety Analysis: what it is & how to make it better

What is a Job Safety Analysis (JSA)? Safety is always a concern on the job site. Safety hazards can put workers in danger, cause serious illness or injury and potentially lead to devastating lawsuits. That’s why many businesses use the Job Safety Analysis (JSA) to help mitigate health and safety risks on work sites. But completing a JSA every day, for every job site, requires a lot of time and effort. It can be easy for workers to half-heartedly complete their JSAs, or ignore them altogether—which can lead to serious consequences. So today, we want to discuss the JSA process, and how you can make it easier using Novacura Flow. Why is it important to conduct a job safety analysis? A job safety analysis (JSA) is a critical first step in promoting workplace safety. By breaking down specific tasks to pinpoint potential hazards, a JSA helps reduce the chances of accidents and injuries, keeping workers safer on the job. In fields like construction, conducting a JSA before each shift and prior to starting work offers a proactive approach to identifying risks that might otherwise go unnoticed. Recognizing hazards early on provides an opportunity to address them, whether through elimination, substitution, or mitigation strategies, reducing the likelihood of incidents. Prevention is key—every accident avoided is a direct result of proactive safety measures and a commitment to zero-injury principles. A well-conducted JSA exemplifies this commitment, reinforcing that safety is not only a priority but a continuous process. For employers, job safety analysis brings additional benefits beyond worker protection. A thorough JSA can improve job site efficiency by reducing delays associated with unaddressed hazards and compliance issues. Identifying risks in advance allows employers to manage resources more effectively and ensure regulatory compliance, ultimately saving time and reducing operational costs. Though a JSA is just one part of a broader workplace safety program, its impact on reducing accidents and fostering a safe, compliant environment can be significant. How many JSAs should a company conduct? Ideally, you would conduct a JSA for every business process—but that takes a lot of time and effort. Focus your efforts on the processes: where previous injuries have occurred that are high-risk tasks You will need to update the JSA whenever conditions change. This can mean changes to equipment, location, or even weather: if the business process changes in any way, you need to review/update the JSA too. You should also review and update the JSA whenever injuries occur on the job. Best practice is to review, and update as required, prior to beginning the task. How to create a JSA Map the process Maybe you’ve already done this. If so, awesome! You’ve already built the foundation of a successful JSA. If not, you’ll want to start by breaking the process down into tasks. For example, if you were to create a JSA for drinking your morning cup of coffee, you might start with something like this: Task Hazard Recommendations Pour coffee in cup Add sugar to coffee in cup Drink coffee Identify the safety hazards associated with each step of the process For […]

learn more

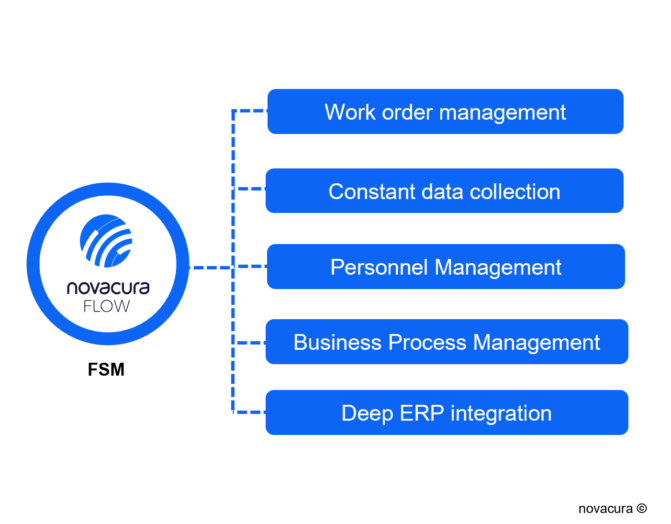

Field Service Management Software connected to ERP

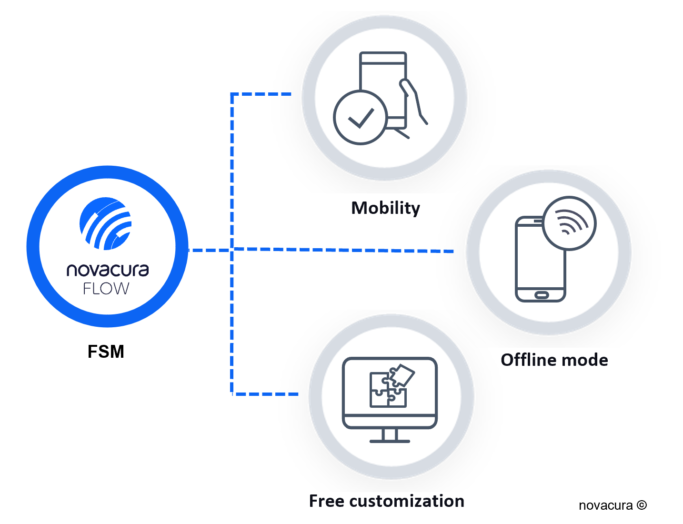

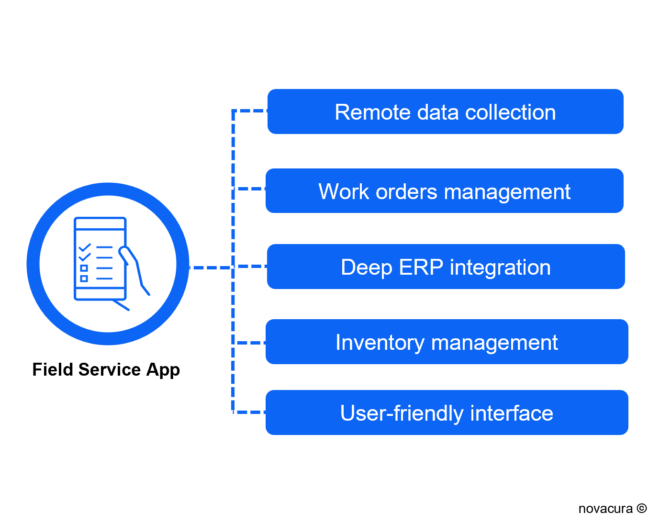

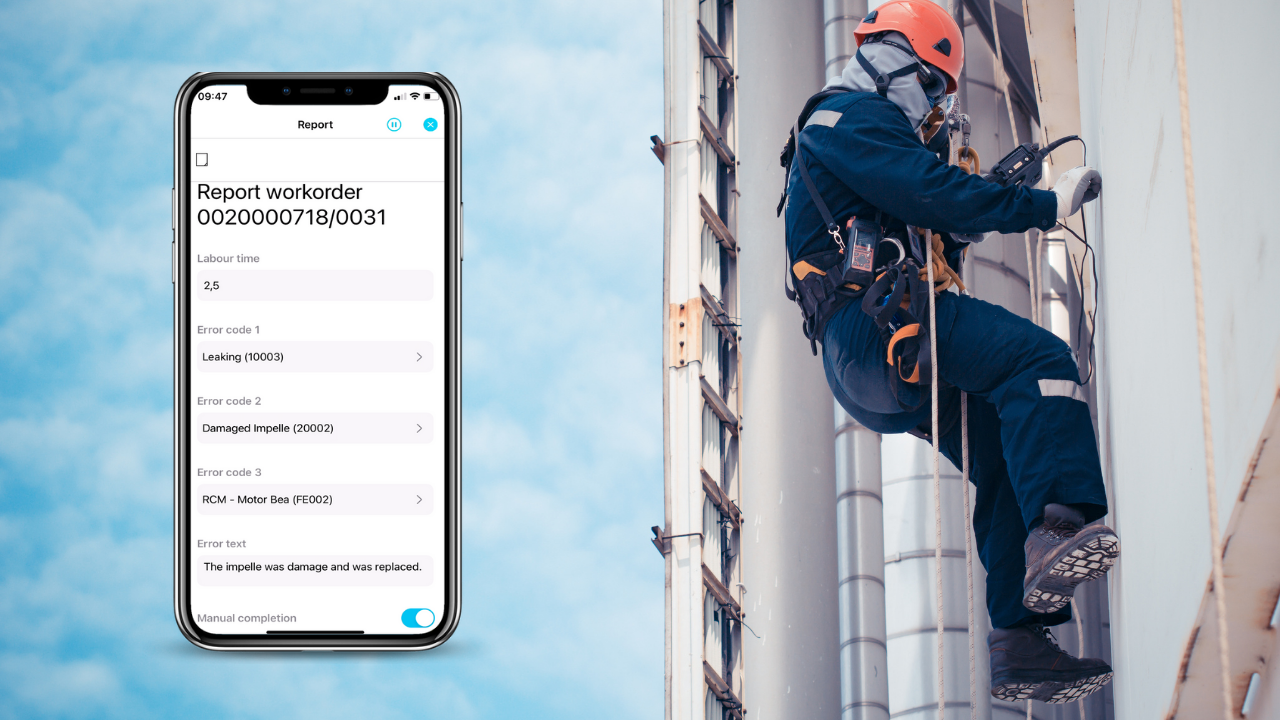

Today, companies that operate in field services and provide maintenance are often closely dependent on ERP systems. However, ERP capabilities often go far beyond the scope of FSM processes, which can only be supported by highly customized software tailored to the specific needs of service industry businesses. The system transactions in ERP allow the organization to run basic operations but does not include the detailed data needed to perform all operations dedicated to FSM effectively. For this reason, field personnel still perform FSM-related tasks with typical paperwork in their hands and then record manually in the ERP system. Manual data entry causes many discrepancies in the system and delays, which lead to much more serious problems and can have significant financial consequences. In addition, inefficiencies in FSM lead to problems with data flow, which is very important for industries that provide services such as public transport, logistics, energy supply, railway installations maintenance, machinery maintenance in manufacturing, and many others. Only a company with mobile solutions for industrial maintenance in the hands of its personnel will be effective enough to deal with the day-to-day business problems associated with field services and maintenance in a highly dynamic environment. What is field service management software? Enterprise Field Service Management software is a system that provides personnel with the capabilities to perform field services and maintenance. Organizations that depend on industrial installations in different locations around big cities and the entire country must often provide services to these installations to ensure their continued functionality. Therefore, the FSM software capabilities should deliver these functions: Mobile access: the FSM should provide mobile applications that can be used by field personnel on mobile devices where they can perform checklists, record damages, system functionality faults, and all operations that are needed for their industry-specific equipment and installation requirements. Offline mode: organizations that are location-dependent with limited network access should be able to record data on mobile devices that can be updated in the ERP system when the network is available again. The Novacura apps have an offline mode. Field workers can retrieve information about the equipment needed for the inspection or reparations and then update the data in the central system. System customization: each industry requires a different approach to field service and maintenance, and business requirements can change; therefore, FSM should be easy to adapt when needs increase or system transaction models change. Real-time data sharing: the FSM is dependent on remote field staff, but the decision-making process should be centralized; therefore, it is important that the FSM continuously provides real-time data to the central management unit to allocate existing resources better. Work order management: the FSM should provide functions accessible from mobile devices that allow easy material pre-order, tool/equipment allocation, process step updates, and even direct access to work instructions with remote assistance. Personnel management and scheduling: the FSM should have built-in functionality for allocating various resources and scheduling personnel, which is critical for any field service to provide services in a timely manner and schedule sufficient working hours, as well […]

learn more

What are the benefits of FSM software from Novacura Flow?

The maintenance role in various industries focuses on a management approach that predominantly relies on time-driven scheduling or repetitive tasks such as inspection of equipment, monitoring of plant conditions, or in some cases, lubrication of mechanical components. The oil and gas, refining and distribution, transportation, construction, and building development industries require continuous field service and maintenance to prevent catastrophic failure modes. The maintenance should provide periodic adjustments to maintain the required levels of reliability and availability. The complexity of today’s field service management cannot be handled simply and cost-effectively without the support of FSM software, which brings definitive advances to the business when it comes to personnel management, failure detection and preventive action, data analysis, forecasting, and even inventory management. The implementation of FSM software guarantees efficient operations through sustainable methodologies and field service management techniques. The only software that can provide maximum flexibility with configurable features will be the most suitable to cover an organization’s functional requirements for field services. Why use field service management software? Companies should consider implementing FSM software for several reasons. Here are the main factors that drive the need to implement FSM software: Intensifying energy efficiency – maintenance can prevent uncontrolled energy consumption, as well as eliminate increased energy consumption by inefficient electrical equipment or installations that may need to be replaced with modern technology. In this way, companies can use less energy but also take advantage of various asset management models that are important for site management and generally towards building efficiency, which among others, can help reduce water consumption, etc. Standardise procedures, time, and costs – companies use maintenance to reduce or prevent the expense of major equipment failures, which tend to be more costly. Companies can also minimize spare parts inventories, reduce the need for backup equipment and increase equipment uptime, which automatically creates maximum production revenue. Systematic strategy – with FSM software, companies can implement various maintenance models, such as preventive, corrective, and predictive maintenance, to help develop a strategy and action plan for planned services and relocation of resources during operational failures caused by plant failure. Companies can also benefit significantly from workforce management by reducing overtime, providing a better workload balance, and managing tasks and contracts. Safety and supporting the energy transition – transport and plant management have an impact on climate change, the maintenance of which can reduce business requirements and plays an important role mainly related to reducing waste, pollution, and carbon emissions. In this case, companies use FSM software to improve safety and pollution control. Continuous optimization – FSM software can help stimulate initial action rather than reaction, indicates support to the user from a continuous improvement perspective, as well as improving equipment reliability over time that ensures consistent quality. FSM software provides both short- and long-term value to corrective actions, which will have a positive impact on ROI. What are the 5 types of service industry? Industrial services for FSM include various installations and equipment at remote locations but also at various stations and plants. Here some of the […]

learn more

Field service management software that connects to IFS: key benefits

Service and maintenance projects necessitate focused attention on FSM-based control systems. The intricacies of service work highlight that FSM can optimize efficiency only when underpinned by customizable software that aligns with business requirements. When determining a cost-effective approach to procuring FSM software, companies should assess its integration capabilities with ERP systems. This approach enables businesses to maintain lower costs when expanding the ERP system with supplementary FSM functionalities. Utilizing the right FSM software facilitates the customization of functionalities without the need for external software development support. Consequently, this approach ensures ERP modifications remain cost-free, effectively establishing the FSM software as an independent layer integrated atop the ERP. Some ERP providers, such as IFS, offer specialized integration capabilities that connect the ERP system with FSM software. This integration empowers IFS users to manage field service and maintenance functions within a segregated system environment. This enables IFS users to align maintenance standards with business objectives, with a strong focus on cost efficiency. Linking FSM software to an IFS ERP system enhances a company’s technological capabilities, delivering numerous benefits, including free customizations and more (as detailed below). What is field service management software? Many industrial companies are required to adhere to particular standards related to health, reliability, customer satisfaction, safety, quality, and even security. Field service management software plays a crucial role in upholding and preserving these standards, facilitating the use of digital systems to collect data and carry out essential tasks. FSM software facilitates the integration of data from ongoing operations into all maintenance practices and methods. This empowers maintenance departments to oversee their work, enhance the efficiency of maintenance tasks, address customer concerns, and respond to emergency situations effectively. Internal: An in-house maintenance structure that relies on internal resources and operates independently, managing facilities and remote installations using only the company’s own personnel. External: Involves external organizations that provide the required assistance independently, often utilizing third-party services to maintain the operational efficiency of equipment and installations. What is a field service platform? FSM software comprises two primary components that collectively play a crucial role in overseeing operations at remote locations. Together, they constitute an integral field service platform. These essential components for effective field service and maintenance management include: Mobility: FSM software should offer mobile functionality for field workers who utilize customized mobile applications on their mobile devices. This empowers them to conduct equipment and installation inspections with enhanced speed and accuracy, ultimately improving the efficiency of maintenance operations. Portals: FSM software should facilitate comprehensive control over field operations through a centralized administrative hub. Here, managers and shift planners can meticulously plan maintenance schedules, make informed forecasts, and devise maintenance strategies based on pertinent operational needs, all within a single interactive portal. This consolidated view allows for a more streamlined approach to maintenance management. Indeed, only a select few systems in the market offer a complete maintenance platform that aligns with the comprehensive criteria needed for FSM software. Novacura presents the Novacura Flow software solution, which functions as a service platform, delivering users with the full spectrum of FSM capabilities along with a platform […]

learn more

IFS Field Service Management with Novacura Flow

Maintenance and field services for equipment and all electromechanical systems are becoming a strategic tools in most industries, regardless of equipment and network extension complexity. Monitoring the entire business system and networks provides operational dynamics analysis and supporting technologies to prevent unexpected events that can cause massive operational problems and unplanned downtime. Field services are needed to ensure the equipment’s ability to accurately determine the operating condition and isolate the root cause of possible aberrations. Field services and maintenance are mainly applicable to industries that depend on equipment located in remote locations and local installations in their premises. These operations involve property management, which is very common in high-tech industries. Among these, we can point to telecommunications, the energy industry, construction, building maintenance, the railroad industry, various field services, and manufacturing. For all these industries, it is required to provide services that guarantee the standard functionality of equipment in different locations with mobile access to general services and maintenance systems, which includes warranty repairs, parts management, specific price assessment, personnel scheduling with the definition of working hours along with all the logistics processes involved (GPS scheduling, tracking, and tracing operations). Companies that want to be most efficient in their cost evaluation and process optimization programs within complex service management should take appropriate precautions on preventive and corrective maintenance, as well as maintenance improvement within the autonomous work order. What is IFS field service management? Process optimization programs include equipment control systems that give a company the correct parameters to evaluate its service and maintenance requirements. One of the Field Service Management systems has been introduced by IFS as a process monitoring and optimization program for organizations operating in the field service, high-tech, medical equipment, and telecommunications industries. The IFS Field Service Management software system provides its users with the following capabilities: Optimized planning and scheduling: resource modelling and planning with travel time, route optimization, and working hours. Field service management: work order management and performance management. Customer engagement: CRM capabilities within ERP portlets. Reverse logistics and warehouse repair: parts management that ensures parts flow back to the warehouse and OEM repair providers when required. Intelligent asset monitoring: monitoring technologies with service levels for tracking reparations of individual pieces of equipment. IFS has been the leader of Gartner’s Magic Quadrant for Field Service Management 7 times, and for the last time in 2022. What is an FSM solution from Novacura? The IFS FSM solution has its base on IFS ERP. IFS FSM, despite its extended capabilities, is strictly characterized as an off-the-shelf solution. From this perspective, IFS FSM has limited mobile capabilities in terms of the available customizations that are required in various industries. Novacura offers its fully customized mobile solution for field service management, combined with IFS ERP as a system layer on top of ERP. With this solution, companies using IFS ERP can enhance their capabilities with customized software that allows easy modifications directly by users. Novacura’s FSM solution was developed as part of Novacura Flow software based on a low-code platform. https://www.novacura.com/wp-content/uploads/2022/08/nc-www-app-creation-in-flow.mp4 The example presented […]

learn more

How to optimize cooperation between Production and Maintenance

In our Lunch and Learn session 4th of April 2022, we, among other things, talked about the importance of cooperation between production and maintenance people. People is a keyword here since it’s not the department itself but communication on an individual level. We can improve this communication and minimize downtime by providing the right tools and technology. Effective basic communication Let’s look at an actual use case where we have an operator who needs to change some tool or has a problem with a machine and needs to make a “tool request.” This is where time often is lost, reaching out and trying to find and reach (chase, call, email) the right contact person to solve this request. We at Novacura suggest a better, more practical, and time-saving solution – to do this on a mobile device. You know that it will be notified directly by the best possible resource in the maintenance department. Effective communication for tool requests: Request or order new tools or spare parts directly from the work center Observe the progress of requested tools or parts in the app Standardize maintenance tasks with guidelines for operations Require users to complete a maintenance checklist Collaboration between the operator and maintenance In the lunch and learn session Östen gives us a practical example by looking at both production and maintenance next to each other to illustrate a typical process of a problem. As shown in the illustration below, the first thing people in production do when something doesn’t work as it should is to try to fix it independently. This process varies in the time since it could take a few seconds to restart a machine, or it could be a lengthy process even if they have the skills to solve it. They often have instructions to reach out for help – might be the instrumental, electrical, or mechanical department of your maintenance organization. First, you need to report a problem, get some help and then start looking at how to fix it and let them do the actual repair before you can be up and running again. This typical situation gives us a couple of lead times to measure: Wasted:Wasted time might be a harsh word, but unfortunately, the time is wasted when we try to fix the problem independently but fail. Some companies set the rule not to do this alone or have a maximum of 5 minutes to solve it on your own to avoid wasted time. Mean Time Waiting (MTW):When someone reports an issue, there will be a lead time until someone starts working on this problem and that is the lead time we call “Mean-Time-Waiting.” Mean Time To Repair (MTTR):The actual time it takes to fix this problem. The actual repair is where most companies perform well but still have room to save some wasted time. In the presentation, Östen tells us about a company that managed to eliminate wasted time in MTT, by requiring the operator to stay by the machine during the repair. That way, the person from the maintenance department could get background information on the issue, get some assistance if needed, and […]

learn more

April 17, 2023

April 17, 2023  8 min to read

8 min to read