Quality inspections of the production line using computer vision and Novacura Flow

If you work in manufacturing, you’re probably familiar with the challenge of avoiding defective products. A defect as small as a missing or unidentifiable barcode can result in downtime and disappointed customers. To limit the number of defective products, manufacturing companies struggle to manage these visual quality inspections. This article will introduce how to improve these inspections through computer vision for quality control – a field of artificial intelligence that trains computers to interpret and understand the visual world. Problem – the cost of quality inspections Every company in manufacturing has the challenge of reducing the number of defective products. Quality inspection in manufacturing is a must; otherwise, faulty products will appear one way or another. Defective products can cause damage and result in unexpected expenses, leading to customer complaints, downtime, labor costs, and scrapped products. Therefore, dedicated people are often used as the quality checkpoint, visually looking at the production line – which costs time and money. The quality check is critical, but manual visual quality inspection slows down the production phase since you must ensure the inspector can keep up with the production line. Is it worth it? Well, it’s necessary to ensure high-quality products – even though it’s a costly expense for the company. In some cases, where risk is high, the cost of letting defective products slip through is considered worse. E.g., delivering faulty products to a client/customer could result in lost contracts/agreements. Therefore, it’s essential to avoid these scenarios and reduce errors, even if that often means having a lot of resources in place and a slower production phase. A well-designed systematic quality inspection will have a positive effect on: Downtime Defective product Loss of revenue Lost customers Wasted time Wasted resources & man-hours Wasted money Decreased OEE / utilization And more.. In most cases, posting a person on the production line at each point of quality inspection is often too expensive – so let’s talk about alternatives using new technologies and solutions like computer vision. Solution – reducing defects and human errors by using computer vision analysis The solution is to install relatively inexpensive cameras in locations where you typically place, or would like to place, a person for visual inspections. By using digital images and video from these cameras, we can train computer vision models to perform analysis. These models enable the cameras to accurately identify and classify objects during production line inspections. An edge computing device processes each frame, performs the analysis, and ultimately outputs the result that the model was trained to generate. With these frames from a video, the model can be trained within a few hours to identify defects in real-time wherever you have repetitive quality inspections. We can then use this data to react to what the camera “sees.” Example 1: Best by dates on packaging Implementing object detection and quality control with computer vision on a packaging production line to detect valid printed Best By dates on packaging. This will allow the detection of misprinted, invalid, or missing Best By codes to be removed from production before being boxed and sent […]

learn more

Job Safety Analysis: what it is & how to make it better

What is a Job Safety Analysis (JSA)? Safety is always a concern on the job site. Safety hazards can put workers in danger, cause serious illness or injury and potentially lead to devastating lawsuits. That’s why many businesses use the Job Safety Analysis (JSA) to help mitigate health and safety risks on work sites. But completing a JSA every day, for every job site, requires a lot of time and effort. It can be easy for workers to half-heartedly complete their JSAs, or ignore them altogether—which can lead to serious consequences. So today, we want to discuss the JSA process, and how you can make it easier using Novacura Flow. Why is it important to conduct a job safety analysis? A job safety analysis (JSA) is a critical first step in promoting workplace safety. By breaking down specific tasks to pinpoint potential hazards, a JSA helps reduce the chances of accidents and injuries, keeping workers safer on the job. In fields like construction, conducting a JSA before each shift and prior to starting work offers a proactive approach to identifying risks that might otherwise go unnoticed. Recognizing hazards early on provides an opportunity to address them, whether through elimination, substitution, or mitigation strategies, reducing the likelihood of incidents. Prevention is key—every accident avoided is a direct result of proactive safety measures and a commitment to zero-injury principles. A well-conducted JSA exemplifies this commitment, reinforcing that safety is not only a priority but a continuous process. For employers, job safety analysis brings additional benefits beyond worker protection. A thorough JSA can improve job site efficiency by reducing delays associated with unaddressed hazards and compliance issues. Identifying risks in advance allows employers to manage resources more effectively and ensure regulatory compliance, ultimately saving time and reducing operational costs. Though a JSA is just one part of a broader workplace safety program, its impact on reducing accidents and fostering a safe, compliant environment can be significant. How many JSAs should a company conduct? Ideally, you would conduct a JSA for every business process—but that takes a lot of time and effort. Focus your efforts on the processes: where previous injuries have occurred that are high-risk tasks You will need to update the JSA whenever conditions change. This can mean changes to equipment, location, or even weather: if the business process changes in any way, you need to review/update the JSA too. You should also review and update the JSA whenever injuries occur on the job. Best practice is to review, and update as required, prior to beginning the task. How to create a JSA Map the process Maybe you’ve already done this. If so, awesome! You’ve already built the foundation of a successful JSA. If not, you’ll want to start by breaking the process down into tasks. For example, if you were to create a JSA for drinking your morning cup of coffee, you might start with something like this: Task Hazard Recommendations Pour coffee in cup Add sugar to coffee in cup Drink coffee Identify the safety hazards associated with each step of the process For […]

learn more

How to improve material traceability in manufacturing

Inventory control over a long period of time can no longer rely on manual data entry using paper forms. The dependence on the manual data entry method cannot be verified in a short period of time and can cause inventory discrepancies that have serious financial implications for the organization. Traceability of goods in manufacturing requires digital inventory management software. Production clerks equipped in mobile devices with embedded software can take control of the entire inventory management process. Handheld computers and mobile scanners operating with barcodes, QR codes, RFID technology are able to ensure proper supervision of the internal flow of materials. Providing barcode material labels when products are inbounded is the solution that should be implemented in any factory. There is no doubt that the use of mobile devices with embedded operate software in manufacturing can influence all stages of production and increase its quality of: Material consumption – consumption registering and preventing shortage ofraw materials. Processing inbound – good traceability from dock registration to inventoryputaway process. Order picking – accurate collection from direct stock locations. Packing and pelletizing – easy determining delivery destination and good quality order checks. Outbound and shipping management – efficient dispatch and reliable ETA withtrack & trace. Inventory control – quick inventory control and accurate cycle count. What is manufacturing traceability? Manufacturing traceability refers to the ability to monitor and track materials, parts, and products—whether individually, by batch, lot, or shipment—throughout the entire manufacturing process and into the supply chain. This capability has evolved significantly from the days of manual records and paper-based tracking. The introduction of barcode technology was transformative, enabling manufacturers to track any item associated with a barcode, including raw materials, components, subcomponents, and finished goods. Modern manufacturing traceability systems go further by leveraging advanced tools like barcodes, RFID, and data analytics to provide real-time visibility into production processes, not just physical items. This comprehensive traceability begins the moment raw materials and parts enter production and continues until the final product exits the facility. By offering detailed insights into each stage of production, today’s systems help manufacturers ensure quality, boost efficiency, and maintain regulatory compliance, ultimately enhancing operational control and customer satisfaction. Manufacturing in the COVID-19 era – Top 3 challenges and how to overcome them (PDF) Top 3 challenges for manufacturers during the pandemic What are the root causes of the challenges? Proposed solution How to implement iT Download Effective traceability of materials Embedded software connected to ERP systems can be enough to fulfil general needs of particular warehouse management but its customization is almost impossible. Modification of ERP system is difficult and time consuming therefore any sort of random software cannot be suitable for complexity of production process. The manufacturing industry is closely dependent on the dynamic changes occurring in each industry sector. Ongoing changes regarding market demand are forcing factories to respond. Adjusting production lines and Warehouse Management Systems (WMS) is already part of its strategy. To secure effective material traceability, manufacturing facilities should consider selecting the most appropriate solution with the possibility of flexible software modification. The software should not only be suitable for the existing hardware, but […]

learn more

Shop Floor Data Collection Software: How to integrate equipment with business systems

To manage means to measure. And your management decisions are as good as the quality of data you used to base them on. Management decisions are made based on “business systems” (Reporting systems – business intelligence, ERP systems, Planning systems APS, MES systems). But these systems have problems with acquiring appropriate information from original information sources. Integrating the systems would be a solution to this, but it’s challenging due to two problems: On the Shop floor side – different devices have different protocols, some are new and some can be over ten years old. There are various business systems on the IT Systems side (APS, MES, ERP, MRP, WMS, QMS). They all use different protocols, provide other information and have independent databases (usually not synchronized). What Is Shop Floor Control Software? Shop Floor Control (SFC) software typically – but not always – part of a Manufacturing Execution System (MES), is a tool that captures, compiles, and analyzes the data needed to make your manufacturing tractable. This set of software constantly gathers data on human input as well as automated systems to inform what is happening right on the shop floor as work is in progress. With shop floor management software, you gain the ability to monitor every detail of factory activity in real time. Detailed reports can reveal essential metrics such as machine runtime, material usage, work remaining, and overall production efficiency. These insights empower managers to make timely, informed decisions that can improve productivity and reduce downtime. Moreover, SFC software can provide a broad perspective that spans multiple departments, individual machines, or even various manufacturing sites. This capability allows for the tracking of key performance indicators (KPIs) from numerous data sources, offering a comprehensive view of the factors driving your company’s production performance. By leveraging SFC software, businesses can pinpoint areas for improvement and better understand the variables influencing their overall output, helping to optimize operations and support continuous improvement across facilities. Solution The low-code BPM platform, Novacura Flow can integrate with all devices on the shop floor side as well as all systems on the IT side. This makes it an ideal solution for bridging the gap between equipment and business systems. Protocols that Novacura Flow support – by devices side How we can communicate with different products: Via a rest-based IoT-Hub, as Azure IoT Via a OPC-UA server Via a machines PLC over ModBus Directly with a machine over TCP/IP Directly from the Novacura Flow-app with a device over BLE (Bluetooth Low Energy) What type of equipment can we connect? Production Robots – automatically read all information, detect downtime, track the number of cycles, and identify alerts. Vision AI cameras – to identify mistakes, take action and record the “incident” for quality purposes Semi-automated Machines used for production – like CNC, 3D Printers – as above, to read information about performance progress, number of prepared components, downtime, alert detection Different gauges/measurers – measure various parameters on the shop floor, such as dust, humidity, temperature, noise, vibrations, and power consumption (including voltage and amperage). Internal access control system – to monitor if a worker leaves or […]

learn more

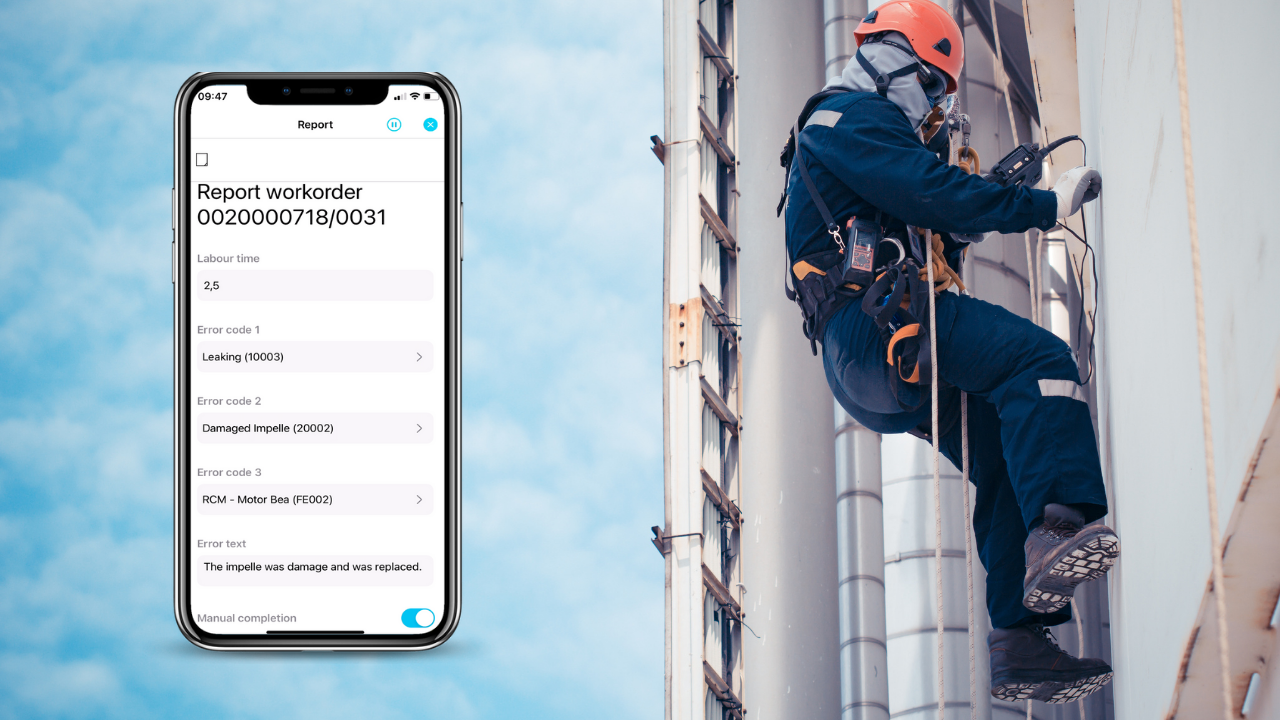

Field Service Management Software connected to ERP

Today, companies that operate in field services and provide maintenance are often closely dependent on ERP systems. However, ERP capabilities often go far beyond the scope of FSM processes, which can only be supported by highly customized software tailored to the specific needs of service industry businesses. The system transactions in ERP allow the organization to run basic operations but does not include the detailed data needed to perform all operations dedicated to FSM effectively. For this reason, field personnel still perform FSM-related tasks with typical paperwork in their hands and then record manually in the ERP system. Manual data entry causes many discrepancies in the system and delays, which lead to much more serious problems and can have significant financial consequences. In addition, inefficiencies in FSM lead to problems with data flow, which is very important for industries that provide services such as public transport, logistics, energy supply, railway installations maintenance, machinery maintenance in manufacturing, and many others. Only a company with in-house mobile capabilities in the hands of its personnel will be effective enough to deal with the day-to-day business problems associated with field services and maintenance in a highly dynamic environment. What is field service management software? FSM software is a system that provides personnel with the capabilities to perform field services and maintenance. Organizations that depend on industrial installations in different locations around big cities and entire country must often provide services to these installations to ensure their continued functionality. Therefore, the FSM software capabilities should deliver these functions: Mobile access: the FSM should provide mobile applications that can be used by field personnel on mobile devices where they can perform checklists, record damages, system functionality faults, and all operations that are needed for their industry-specific equipment and installation requirements. Offline mode: organizations that are location-dependent with limited network access should be able to record data on mobile devices that can be updated in the ERP system when the network is available again. The Novacura apps have an offline mode. Field workers can retrieve information about the equipment needed for the inspection or reparations and then update the data in the central system. System customization: each industry requires a different approach to field service and maintenance, and business requirements can change; therefore, FSM should be easy to adapt when needs increase or system transaction models change. Real-time data sharing: the FSM is dependent on remote field staff, but the decision-making process should be centralized; therefore, it is important that the FSM continuously provides real-time data to the central management unit to allocate existing resources better. Work order management: the FSM should provide functions accessible from mobile devices that allow easy material pre-order, tool/equipment allocation, process step updates, and even direct access to work instructions with remote assistance. Personnel management and scheduling: the FSM should have built-in functionality for allocating various resources and scheduling personnel, which is critical for any field service to provide services in a timely manner and schedule sufficient working hours, as well as prepare a quick replenishment and inform staff when needed. Reporting: data […]

learn more

IFS warehouse – WMS functionality

Efficiency in the warehouse relies on the proper functioning of an ERP system. Material handling and warehousing systems are crucial for expanding operational capacity and meeting the rigorous standards of global economies. Businesses should exercise caution when choosing an ERP system, considering key indicators in their final decision. The best ERP system should offer a warehouse information exchange system that ensures a seamless flow of data, simplifying information collection, processing, and presentation to users. Equally important is how the system handles decision-making and processes. One of the market leaders in ERP systems is IFS, which provides essential core business functions capable of integrating all departments. IFS demonstrates heightened efficiency when paired with WMS functions within the ERP system. The primary benefits of augmenting ERP with WMS include: Labor: Minimizing manual operations through mobile solutions and enhanced staff management, offering a holistic view and control over productivity. Inventory and Inventory Costs: Reducing inventory discrepancies by improving manual operations related to allocation units, relocations, shipping, cycle counting, storage, and more. IFS WMS The most common approach to building a business case for a WMS involves evaluating a company’s current and future requirements. This assessment helps companies determine which WMS solutions are best suited for their warehouse operations. There are three primary types of system solutions that offer WMS functionality: Off-the-shelf (COTS) software: This type of software consists of pre-packaged, commercially available solutions designed to handle standard warehouse operations, such as receiving, a limited range of storage options, and shipping. These solutions typically offer no room for customization, and many tasks still need to be carried out manually. Enterprise resource planning (ERP) software: ERP software integrates various departments within an organization and often includes specific ERP components tailored to meet operational needs. These components are selected to cover the functionalities provided by COTS-WMS software. Custom-developed software: This software is custom-built to address specific operational requirements. It often includes tailored customizations to extend its functionality. However, subsequent upgrades can be costly and time-consuming, frequently requiring support from external programmers. Standard Commercial Off-The-Shelf (COTS) software often falls short in providing extended functionality. Although ERP systems are pivotal in warehouse operations, they may encounter limitations in delivering comprehensive support for the evolving and dynamic needs of a growing business. Conversely, custom-built software might lack the capacity to address unforeseen warehouse challenges that may arise in the future. Each of these options comes with its own set of strengths and weaknesses, underscoring the importance for companies to carefully select the most suitable solution based on their unique operational requirements. The cornerstone of the WMS software designed for IFS was predominantly WADACO, a solution enabling the integration of custom functions as an additional layer to an ERP system. However, numerous international warehouses chose to swiftly enhance their mobile capabilities within operations, presenting a considerable challenge. The task became particularly daunting as constructing a business case for a WMS primarily involved quantifying the financial advantages of digitizing the system. While companies could pinpoint various financial expenses upon assessing their warehouse needs, they found themselves in need of assistance to evaluate the […]

learn more

June 28, 2022

June 28, 2022  5 min to read

5 min to read