- Home|

- Warehouse Management System

Warehouse Management System (WMS)

Solution for IFS and Infor M3

• Delivery and Shipment Management

• Quality Control

• Shop Floor Orders Management and more

Real-Time Inventory Tracking

Mobile Warehouse App

Replenishment & Reorder Control

Integrated Shipping Management

Analytics & Dashboards

ERP Integration

The Warehouse Software is a complete solution for IFS and Infor M3 ERP systems. It includes a suite of mobile applications designed to reduce errors and increase warehouse productivity. Built as ERP extensions, these applications can be activated instantly, improving your processes without complex or time-consuming implementation. All necessary ERP integrations come ready out of the box. In practice, it works as a warehouse software platform that extends your ERP with mobile-first workflows and ready-made connectors.

Who Benefits from WMS:

01

Procurement Managers

Get real-time stock levels and accurate reorder points to plan purchases confidently.

02

CFOs

Reduce frozen capital tied up in excess stock while keeping service levels high.

03

Warehouse Operators

Simplify daily tasks with an intuitive mobile app that reduces errors and speeds up work.

04

Warehouse Coordinators

Track operations with ease, improve efficiency, and onboard new staff quickly thanks to a simple interface.

05

Site Managers

Gain peace of mind knowing materials are always available for production — no supply gaps, no surprises.

06

Shipment Coordinators

Plan shipments accurately and keep clear evidence of each movement.

07

IT & ERP Owners

Go beyond standard ERP limits with a fully mobile, customizable WMS — integrated without costly modifications.

Warehouse software solution - key capabilities

Below we present example features offered by our Warehouse Management extensions for your ERP:

Improve data-entry efficiency with barcodes and RFID

Novacura WMS Package supports two industrial standards especially important in logistics and manufacturing. Users can scan barcodes from any package, asset, or location. This ability is available automatically - each input field in the mobile application offers the possibility to scan the data instead of typing it by using the keyboard. The application can also be integrated with RFID gates and automatically track information about parts and finished goods moved inside the inventory.These features work seamlessly on handhelds and tablets, functioning as a single, standardized warehouse management app across all your locations.

As part of our wms capabilities barcode and RFID data is validated in real time and posted directly to your ERP, ensuring accuracy and eliminating the need for manual data entry.

Print, scan and manage labels directly from the ERP application

Our WMS package is integrated with the labeling systems – Loftware (previously NiceLabel) and BarTender. Our mobile applications can initiate the label printing process and feed the label system with all necessary data. This operation can be done as one of the regular process steps meaning the user doesn't have to care about labels in a separate tool. This integration is bi-directional, which means that the warehouse solution understands all the information encoded on labels. Labeling is built directly into our WMS system, so operators trigger Loftware or BarTender jobs within the process and get status updates back in ERP. As part of our warehouse software solutions, template control and bi-directional label data keep formats consistent and compliant across sites.

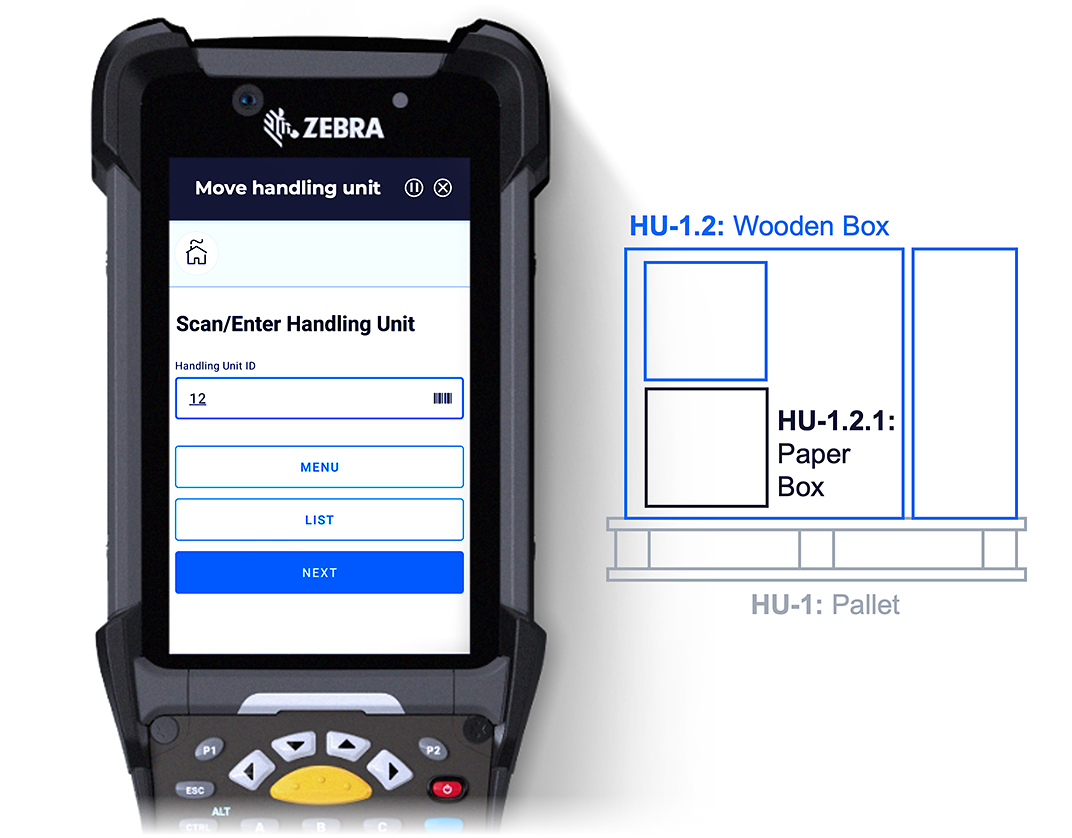

Use handling units

Our solution provides a flexible way to organize materials, components, and parts into packages called handling units. These units can form a hierarchy - example, a small package can be placed in a larger one, which in turn can be stored on a pallet. Handling units make it easy to move entire groups of items at once, whether to another location, the shop floor, or the shipping zone. Instead of moving single items, operators transfer whole packages, significantly increasing warehouse efficiency. The warehouse inventory app fully supports handling units, allowing staff to move packages with just one scan and a single ERP posting.

Optimize picking paths

Picking different materials and components for production might be complicated – warehouse operators have to gather different elements spread out across the entire inventory. And since they operate in a “JIT” environment, they are under time pressure.

Our solution optimizes the picking path based on the location, weight, further unloading sequence, or even expiration date of particular goods. This means that the warehouseman doesn’t have to go “back and forth” to complete the picking list. This dynamic pathing capability eliminates unnecessary travel for warehouse operators, cutting down on walking distance and significantly boosting picks-per-hour. Dynamic pathing is part of our wms solutions for high-throughput sites, cutting walking distance and boosting picks-per-hour. In practice, this showcases the benefits of warehouse management system for JIT operations—less backtracking, faster fulfillment, and fewer errors.

Integrate with the inventory equipment (with iIoT)

Novacura WMS package (powered by Novacura Flow technology) can be integrated with iIoT machinery, equipment and other devices that operate in a warehouse. A typical example where this connectivity may be used is the integration with industrial scales. The weight information can be used to double-check the delivered package, to count materials that return from the shop floor (i.e. the length of the cable), or to verify the contents of the package prepared for shipment. This weight can be automatically read from the scale and the number of goods (or its size) can be then automatically determined. With iIoT connectors, scale readings and device signals flow directly into ERP and the mobile app. This is one of the wms functions that reduces manual entry and errors, and it’s included among our warehouse management system features for faster, more reliable counts.

Pick by voice

Novacura WMS package can be integrated with the “pick-by-voice” technology. With that solution, the warehouseman can listen to the instructions in his headset, having free hands to perform physical operations (which has a huge impact on efficiency). Then, when the requested operation is completed, the warehouseman can confirm it using his natural voice (thanks to the microphone and voice recognition technology). This capability can also be used to perform inventory counting or report anomalies. The same hands-free workflow, which is a key feature of our easy to use warehouse management software, runs in cloud warehouse management systems, enabling operators to follow spoken instructions and confirm steps without breaking pace. This provides centralized setup and reporting across all sites.

Manage your deliveries and shipments

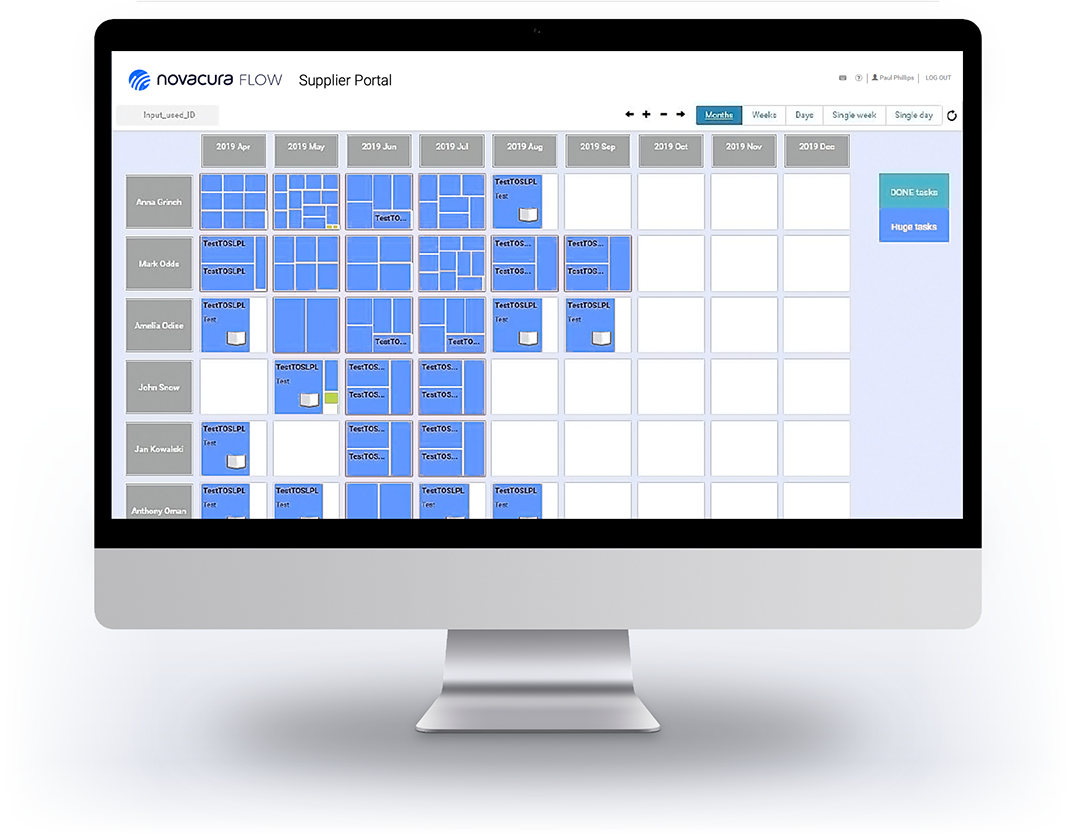

Novacura WMS package is not only limited to supporting the core inventory operations. It also offers support for supplies/delivery management and is used to manage the shipment of goods to customers.

You can use B2B Portal to confirm the delivery schedule with your suppliers and book a suitable time-slot and a free ramp for unloading! It can also be integrated with external transportation exchange systems (like PaceJet) and helps you find an optimal transport method for your shipment. These workflows are part of our warehousing and distribution solutions, linking carrier APIs, dock scheduling, and your ERP in a single place for end-to-end visibility. For omnichannel teams, they also serve as a powerful warehouse management software for ecommerce, handling every step from ASN confirmation to rate shopping and last-mile dispatch.

Recognize your supplier’s codification

Typically, when delivery comes from a supplier, delivered goods are identified by codes according to the supplier’s codification system. These codes must be mapped on the internal coding system that is used within a company for all the goods. Our solution can support multiple codifications for the same goods and can automatically recognize foreign codes and map it onto internal codes.

Integrate with other departments

The ultimate benefit of using our WMS package is that this can be connected with other packages, that support other divisions in the company – quality inspection, production, procurement, maintenance and more. Thanks to that, a warehouseman can pick materials based on the material request issued by the production planning specialist that uses another element of the Novacura package. Or, broken components reported by the shop floor operator can immediately invoke additional internal transportation that will bring the correct components right to the work center. This cross-functional handoff is a core part of the warehouse management system process, connecting quality, production, and maintenance tasks directly to inventory moves. These key functions of a warehouse management system ensure that interdepartmental requests automatically trigger guided workflows, reservations, and confirmations in a single, seamless flow.

Industries We Serve:

01

Manufacturing

From automotive to electronics, ensure materials and finished goods are always in the right place at the right time.

02

Logistics Providers

Optimize inbound, outbound, and cross-docking operations with full visibility and control.

03

Distributors & Wholesalers

Track high-volume stock flows, reduce inventory losses, and increase picking accuracy.

04

Commerce & eCommerce

Manage fast-moving inventory, handle peak seasons efficiently, and improve order fulfillment.

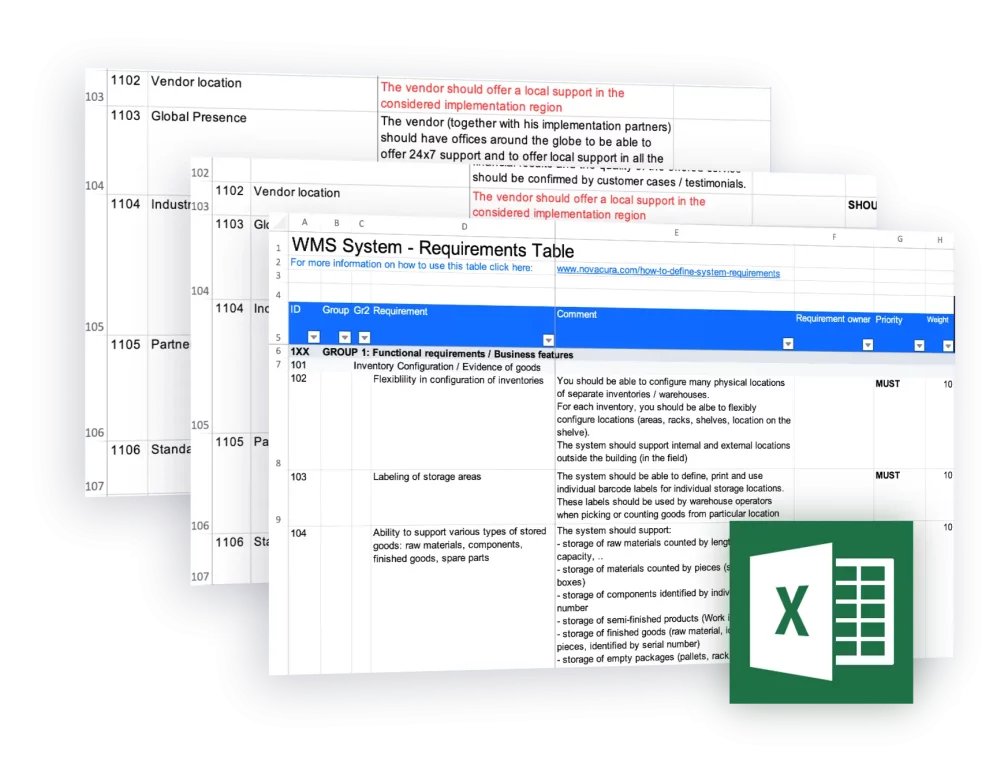

166 Requirements For Evaluating Warehouse Management Software (WMS)

82 Functional + 84 Non-Functional WMS Requirements, directly connected with the warehouse processes in large and medium business. Adapt for your needs, evaluate vendors & more. Novacura – Trusted by 220+ Companies.

FLEXIBLE TECHNOLOGY BEHIND OUR WMS PACKAGE:

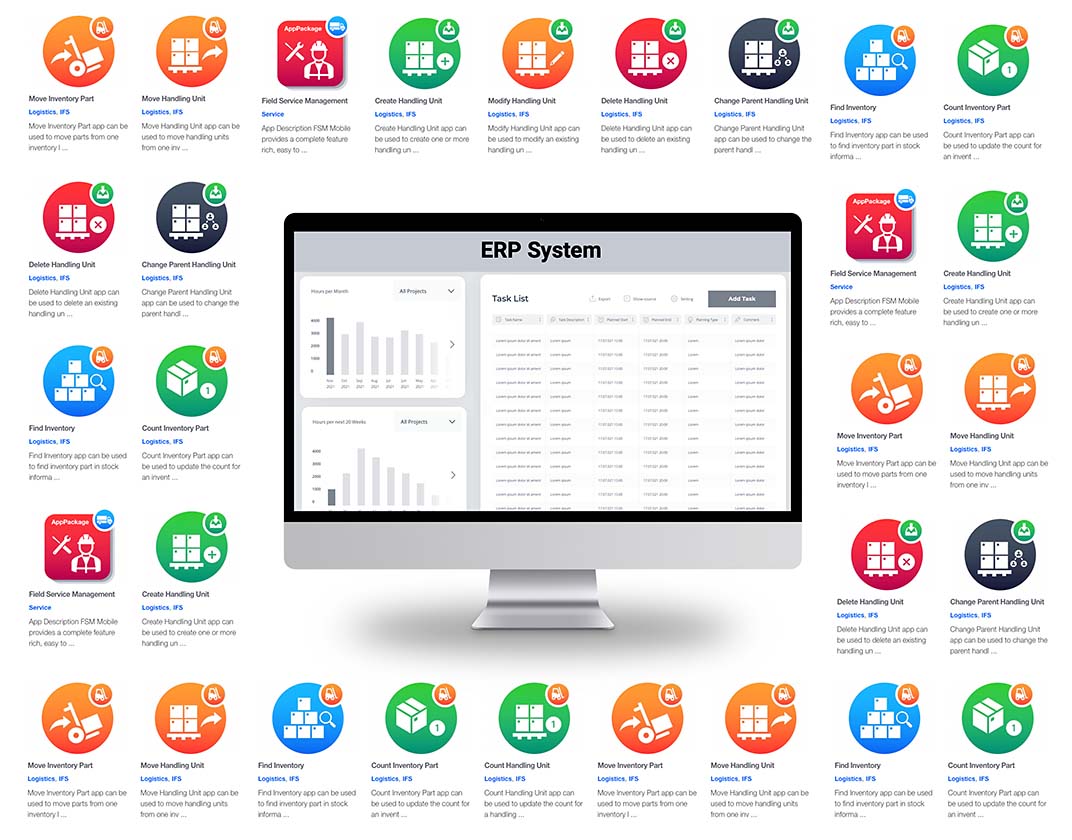

ERP extensions that are fast to implement

Our Novacura WMS Package is built on a strong foundation: it must be easy and fast to implement! We created it as a package of ERP extensions that are dedicated to working with the most popular ERPs (such as IFS, Infor, SAP). With that approach, you can turn them on and start using them. The ERP integration (that is usually the most complicated part) is prepared “out-of-the-box”.

The true benefit of the ERP extensions philosophy is that when you implement these applications, it doesn’t affect surrounding ERP processes – all ERP users will still see all warehouse operations (performed in Novacura) in the ERP, as they used to see them before!

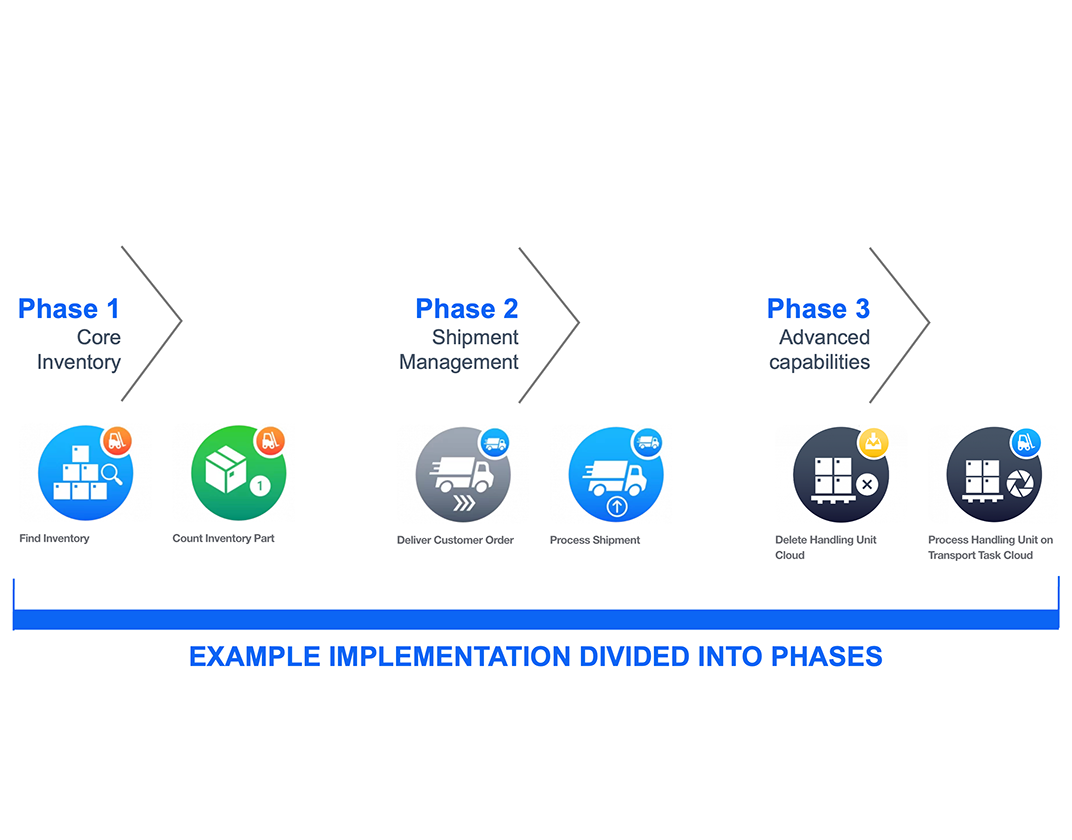

An iterative approach, no revolution needed

Novacura WMS solution offers various applications to support and optimize warehouse operations. As these apps are prepared as ERP extensions, they share the same source of information: the ERP database. As a result, you don’t have to implement all of them at once. If you don’t want to implement some applications in the 1st phase, the standard ERP functionality will still be used instead of them. So you can add them later when the first package of process changes is adopted by your organization. That makes it ideal if you’re comparing types of warehouse management systems or need to start small and scale later.

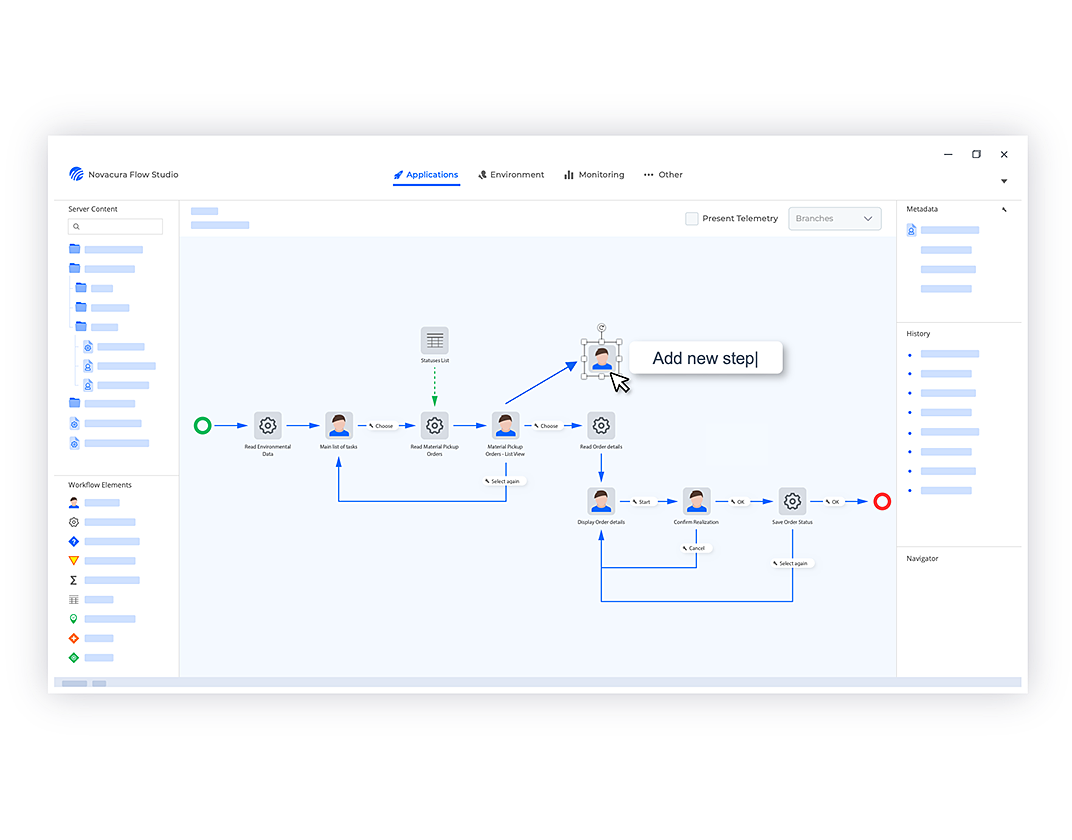

Ready for future changes thanks to the low-code core!

Every company is different from the others. You might have specific processes and require unique features, and we are ready for that! Our WMS Package is based on the low-code platform Novacura Flow. It means that all our applications are not hard-coded. Our customers can modify them or clone them and create variants. And they can build their own applications. And thanks to the low-code engine, they can create apps by drawing them like they draw a business process. This approach effectively gives you a warehouse management platform you can tailor without code-heavy projects. Teams can spin up custom warehouse management software modules to match new workflows, regulatory changes, or site-specific needs.

The Simplified Implementation Process:

The implementation process takes less time than usual. We have a flexible solution that can be easily integrated with existing systems.

1. Mature methodology

We have a mature implementation methodology divided into stages (like initial requirements workshop, feasibility study, etc.) — that way the whole project is predictable and can be fully controlled and coordinated by us.

2. Years of experience

We have 17+ years of experience in logistics. There is a library of ready-to-use applications that can be

presented to the customer and customized according to his needs. And the library is available on the Novacura Flow Marketplace.

3. Low-code platform

Novacura Flow is a low-code platform – so we can implement everything our customer wants, and every element can be adjusted to specific customers’ needs.

4. Industrial connectors

We have a solid base of industrial connectors – the technology is no longer a problem.

Detailed list of warehouse management system features:

Below we summarize the list of areas supported by Novacura WMS package:

01

Suppliers / delivery management

- Stock level management

- Purchase orders management within B2B portal (EDI support)

- Delivery management within B2B portal (JIT system support)

- Double-codification for goods delivered from suppliers - ability to use external labels / codes

- Financial settlements with suppliers within B2B portal

- Integrated carrier communication within B2B portal

02

Internal logistics / production support

- Material requisition processing

- On-demand material delivery orders processing

- Order picking optimization (picking paths optimization, strategies support FIFO, FEFO, LIFO)

- Transportation management for the shop floor (trolleys configuration & delivery route management and planning)

- External inventory usage optimization (delivery time transport duration, production returns management)

03

Finished goods / shipment

- Finished goods storage

- Shipment planning and confirmation with customers (B2B Portal)

- Transportation management, planning (schedulling / adhoc – premium freight)

- Transportation preparation control (packing, loading, warehouse dock and ramp allocation)

- Transportation costs optimizations (route planning, post-analysis)

04

Inventory management

- Material and component storage

- Traceability, batch / LOT identification on every stage

- Handling unit management

- Material movements (inside inventory/ cross-inventory)

- Inventory counting ("on the fly" cycle counting / periodical)

- Aging stock and scrap management

- Locations management (virtual locations, cross-inventory operations)

05

Returnable packaging management

- Packages pool planning based on production demand

- Packages in a loop monitoring

- Package damage reporting

- Packages picking / packaging-sets completing from the shop floor

- Constant packaging quantity control within B2B Portal

- Track & Trace back and forth packaging among distribution center, suppliers and customers

06

Common technology support

- B2B Portals (connecting suppliers, customers)

- Deep ERP integration - dedicated to working with ERP systems as ERP extensions

- Machines Integration (industrial IoT)

- EDI integration

- RFID gates integration

- Barcodes / QR Codes support

- Pick-by-voice technology support

- Computer vision (for visual inspections, truck plates recognition, documents processing)

Contact Us:

Please fill out the form. Our team will respond within 1 business day.

Prefer email? Contact us here: info@novacura.com