February 11, 2026

February 11, 2026  8 min to read

8 min to read For years, the promise of Artificial Intelligence in manufacturing has been hindered by a fundamental disconnect. While modern ERPs can predict a machine failure or a supply chain delay with startling accuracy, the “last mile” of that insight – getting a human or a system to actually do something about it – in many cases remains manual, fragmented, and slow. This is the Industrial AI Paradox: we are data-rich but execution-poor.

With the introduction of IFS.ai and the 2025 acquisition of TheLoops — now integrated as IFS Loops — ERP is evolving into something fundamentally different: a system of action, capable of autonomous execution, real-time decision-making, and continuous operational orchestration.

This shift is not incremental. It is architectural.

IFS.ai: Intelligence As An Infrastructure

IFS has fundamentally rejected the “AI-as-an-add-on” philosophy. Through IFS.ai, they have built an infrastructure where artificial intelligence is a core component of the ERP architecture. This isn’t just about generating text; it’s about industrial-grade predictive and prescriptive logic.

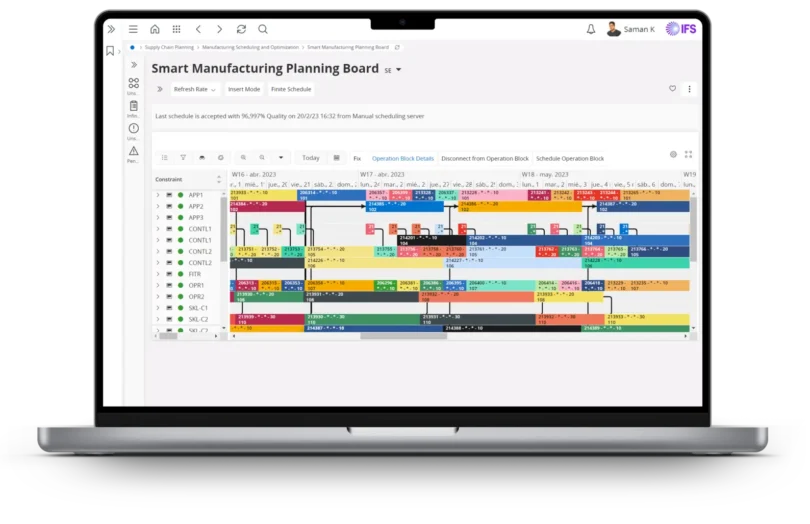

For a Logistics Manager, this means the system doesn’t just record that a shipment is late. IFS.ai analyzes the impact of that delay on downstream production schedules, evaluates the shelf-life of the raw materials involved, and recommends a specific rerouting strategy to minimize financial loss. It is pervasive, touching everything from Enterprise Asset Management (EAM) to Service Management.

For more insights on IFS.ai check out: IFS Cloud – IFS.ai

The Strategic Shift: Why IFS Acquired TheLoops

To understand where industrial software is heading, we must look at the 2025 acquisition of TheLoops.

Traditional ERP systems act as “systems of record,” storing and reporting data after events occur. With the emergence of agentic AI platforms like IFS Loops, ERP evolves into a system of action — autonomously executing multi-system processes and making context-driven decisions while humans focus on high-value exceptions.

IFS Loops: The Rise of the Digital Worker

IFS Loops introduces the concept of the Digital Workers, specialized autonomous AI agents capable of context-aware decision making and execution across enterprise systems. Unlike rigid RPA scripts, they dynamically plan and perform complex tasks such as order management or maintenance scheduling with significant operational impact.

To understand the breadth of this technology, we can categorize these agents by the operational “Villains” they defeat:

- The Supplier Order Manager (The Procurement Sentinel): In a traditional setup, if a supplier changes a delivery date via email or a portal, a human must read the notification, check the ERP, assess the impact on production, and manually update the purchase order. The Loop: The Digital Worker monitors these external signals autonomously. It identifies a 48-hour delay, cross-references it with current safety stock levels in IFS Cloud, and—if the delay doesn’t risk a line-stop—it updates the PO and notifies the planner. If it does risk a line-stop, it automatically flags the exception for immediate human intervention.

- The Demand & Inventory Replenisher (The Capital Optimizer): Manual replenishment often relies on “gut feeling” or static reorder points that don’t account for seasonality or sudden market shifts. The Loop: This agent continuously analyzes consumption patterns against external market signals. If it detects a trend—for example, a sudden spike in demand for a specific spare part in a certain region—it can autonomously initiate a transfer order from a central hub to a local warehouse, ensuring availability without overstocking.

- The Maintenance Dispatcher (The Uptime Guardian): Usually, maintenance is a game of “telephone” between an IoT sensor, a dashboard, and a scheduler. The Loop: When a machine vibration sensor hits a critical threshold (the Signal), this Digital Worker doesn’t just send an alert. It checks the technician’s schedule for the specialized skill set required, verifies part availability in the warehouse, and drafts the Work Order. It effectively “triages” the technical health of the factory in real-time.

- The Customer Service Advocate (The Experience Enhancer): Tracking “where is my order” is one of the most significant time-sinks for logistics teams. The Loop: This agent monitors shipment tracking data. If a delay occurs at a port, it calculates the new estimated time of arrival (ETA) and proactively sends an update to the customer via the portal or email—often before the customer even realizes there is a delay.

By automating routine coordination tasks, Digital Workers free skilled personnel from data gathering and repetitive updates, boosting throughput, lowering error rates, and enabling teams to focus on strategic decision-making and exception handling.

For more insights on IFS Loops check out: IFS Cloud – Loops

With IFS Loops embedded in IFS Cloud, ERP evolves from passive infrastructure into an active operational engine.

For manufacturers and service organizations, this means:

-

Automatic rescheduling when disruptions occur

-

Autonomous spare parts reordering

-

AI-driven maintenance coordination

-

Intelligent case resolution in service operations

This is not dashboard AI.

This is operational AI.

Novacura Flow Connect – The Execution Layer

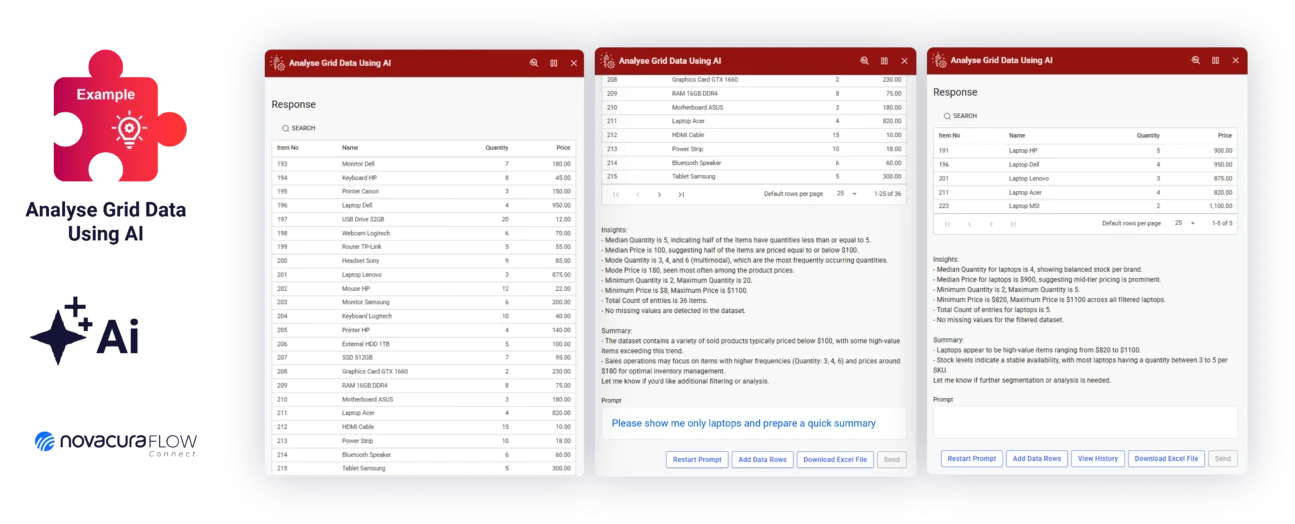

While IFS Loops provides the AI execution layer, Novacura Flow Connect serves as a rugged execution layer bridging industrial workflows — capturing data, translating AI triggers into actionable tasks on rugged devices, and orchestrating cross-system processes, including legacy systems. This addresses the real industrial “last mile”.

Flow Connect serves as the process-optimizing layer that makes AI actionable in three specific ways:

- AI-Enhanced Data Capture (OCR & Normalization): AI is only as good as the data it consumes. Through the Novacura Marketplace, companies can deploy “Ready-Made AI Solutions” that use OCR to scan incoming supplier invoices. Flow doesn’t just “read” the text; it uses AI to normalize the data (e.g., converting “units” to “kilograms” based on ERP logic) before it ever reaches IFS, ensuring the Digital Workers are acting on accurate information.

- Bridging the “Last Mile” UI: A predictive maintenance alert generated by IFS.ai is useless if it stays in the back office. Flow Connect can intercept that AI trigger and instantly push a guided workflow to a technician’s mobile device. The technician sees a simplified interface that tells them exactly what to do and which parts to take, ensuring the AI’s insight leads to a physical result.

- Cross-Ecosystem Orchestration: Most manufacturers operate in a “hybrid” reality. Flow Connect acts as the “Universal Connector,” allowing an AI-driven decision in IFS Loops to trigger an update in a legacy MES or a third-party CRM, ensuring the “Loop” isn’t broken by a software boundary.

Turning Foresight Into Profit

The ultimate “Victory” in the AI journey is the total elimination of the reporting lag. The goal is to move from a “reactive” posture to one that is “predictive and proactive.” When you bridge the intelligence of IFS.ai with the mobile-first execution of Novacura Flow, the ROI compounds. You aren’t just reporting what happened faster; you are preventing issues before they occur.

- Guaranteed Compliance: A low-code layer like Flow ensures that the “smart” schedule created by AI is followed to the letter. It forces mandatory quality inspections—such as temperature checks or pressure readings—to be performed at the exact moment the AI-driven process demands them, ensuring 100% adherence to safety standards.

- Operational Resilience: By offloading routine coordination to Digital Workers, organizations can maintain high output even during labor shortages. The “on-the-ground” staff are never left wondering what to do next; they are always guided by the system to the highest-priority tasks, as determined by real-time AI logic.

- Synchronized Supply Chain: When AI-driven foresight in the ERP is connected to the physical movement of goods via Flow, the result is a supply chain that can “self-correct” in the face of volatility.

It is important to recognize that even the most advanced AI "brain" can struggle with the "last mile" of industrial reality for several technical reasons:

The "Last Mile" UI Gap: Standard ERP interfaces and AI chatbots are often too "heavy" for high-volume shop floors. A worker scanning a thousand items an hour or operating in a hazardous area cannot stop to interact with a complex screen. Novacura Flow provides the high-speed, simplified "ruggedized" interface that makes AI insights actionable in seconds.

Summary

The convergence of IFS.ai, IFS Loops, and Novacura Flow represents more than product integration. It signals a structural shift in enterprise architecture. ERP is no longer just the backbone. It becomes the operational nervous system. Data becomes action. Workflows become autonomous. And industrial enterprises move from reactive operations to intelligent execution at scale. The evolution from system of record to system of action is not theoretical. It is already underway.