- Home|

- Returnable Packaging Management System (RPMS)

Returnable Packaging Management System (RPMS)

Solution for managing packaging flows with Suppliers.

- Built on Novacura Flow – flexible low-code platform

- Complete returnable containers management across plants and external warehouses

- Supplier portal for collaboration and reconciliation

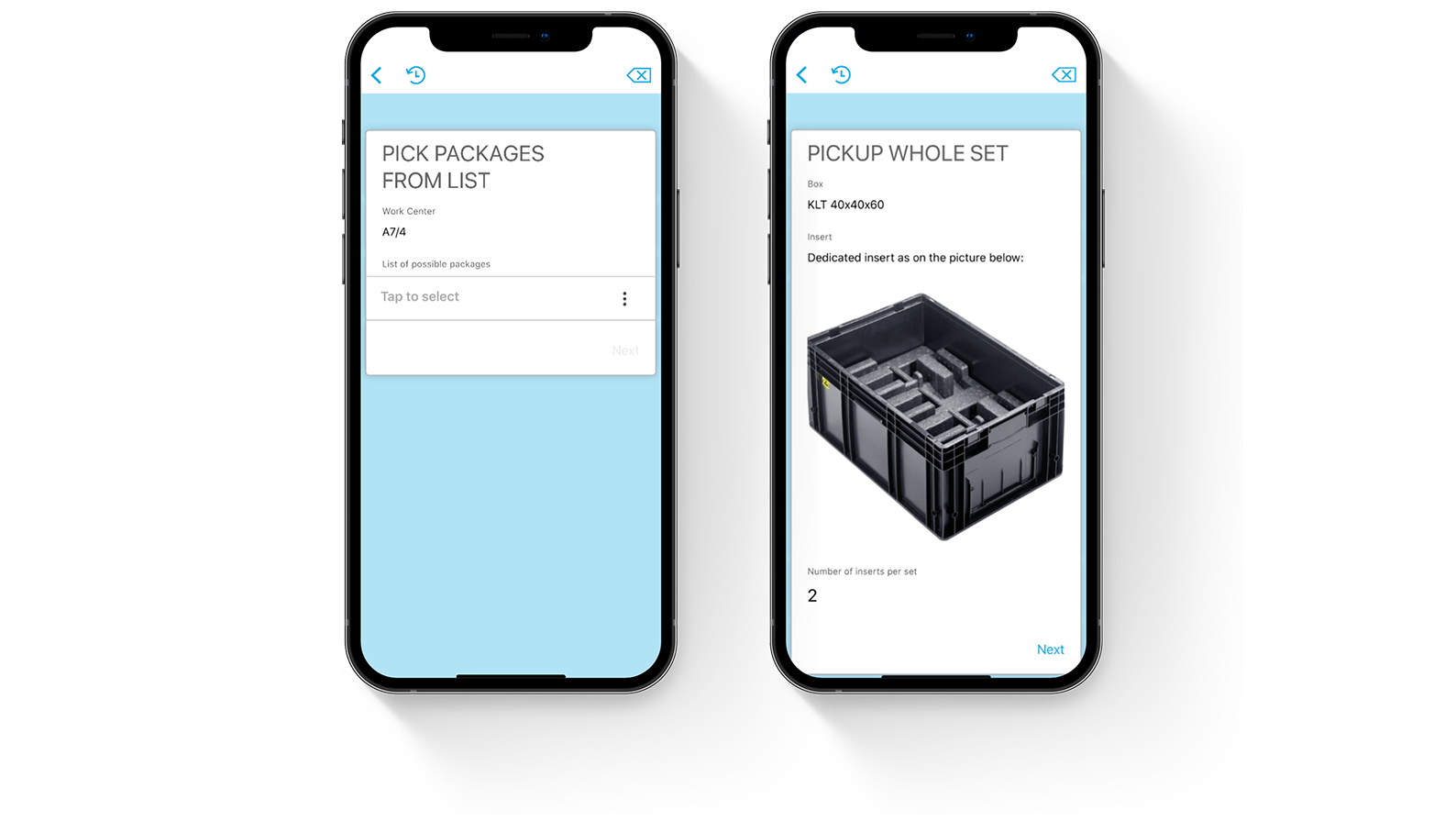

- Mobile apps for logistics staff (scanners, handhelds)

Real-Time Tracking

Always know where your packaging assets are across plants, warehouses, and partners.

ERP & WMS Integration

Connect seamlessly with existing systems — no costly modifications needed.

Mobile Scanning

Track packaging with handheld devices and smartphones, directly on the shop floor.

Automated Reconciliation

Eliminate manual counts and balance your packaging loops instantly.

Supplier Portal

Collaborate with suppliers to streamline returns and reduce packaging losses.

Analytics & Reporting

Gain insights into usage, rotations, and CO₂ savings with built-in dashboards.

Introduction

Our Returnable Packaging Management System (RPMS) is engineered for companies that rely on returnable packaging management in their supply chain. The solution ensures that containers and packaging sets circulate smoothly between suppliers and your plants, minimizing losses, improving visibility, and reducing logistics costs.

Built on the Novacura Flow low‑code platform, RPMS is flexible, extendable, and future‑proof. You can adapt it to your processes, integrate with SAP or other ERPs, and add new functionality as business needs evolve—without heavy ERP modifications.

Who Benefits from RPMS:

Our Returnable Packaging Management System is built for everyone who needs control, visibility, and cost savings around packaging flows — from strategic decision-makers to day-to-day operators.

01

Supply Chain & Logistics Leaders

Track packaging across the entire loop — plants, warehouses, suppliers, and customers. Quickly identify bottlenecks, optimize the number of containers in circulation, and reduce costly losses.

02

Site & Facility Managers

Prevent shipment delays caused by missing packaging and avoid penalty costs. Ensure containers are always available when and where they are needed.

03

Operations & Warehouse Managers

Guarantee packaging availability for production and outbound shipments. Eliminate manual work by tracking containers with mobile scanning and automated reconciliation.

04

Internal Logistics Operators

Easily monitor packaging items delivered to and collected from production zones. Reduce errors and keep packaging flows running smoothly on the shop floor.

05

Procurement Managers

Cut recurring spend on lost or excess packaging. Gain accurate usage data to improve supplier contracts and plan budgets with confidence.

06

Sustainability Managers

Demonstrate measurable ESG impact. Track reuse cycles, cut waste, and report CO₂ savings through transparent packaging data.

07

IT & ERP Owners

Go beyond the limited functionality of standard ERP modules. Replace costly modifications with a fully mobile, customizable solution — seamlessly integrated into your ERP and WMS landscape.

Key Capabilities:

Receiving Deliveries

At the inbound dock, packaging is recorded alongside materials, ensuring every returnable container is tracked from the first step. Workers can register packaging by material type, by barcode scan, or through manual entry when data is incomplete. The system auto‑validates against packaging configuration and highlights mismatches. Ownership is resolved immediately (supplier‑owned, customer‑owned, or rental) based on contract rules.

Issuing to Production

When materials are issued to the shop floor, RPMS automatically proposes the correct packaging configuration based on SAP pick lists. Logistics staff can confirm with a single tap, yet still adjust manually if reality differs. Any packaging previously flagged for verification must be confirmed before release, keeping data quality high and ensuring that only valid sets enter production.

Returning from Production

Once materials are consumed, returnable containers flow back from production. RPMS helps verify completeness of each set—checking inserts, lids, and boxes. Workers scan the workstation, and the system instantly displays which packaging should be present. Damaged or incomplete sets can be flagged with photos, ensuring issues are addressed before containers re‑enter the loop.

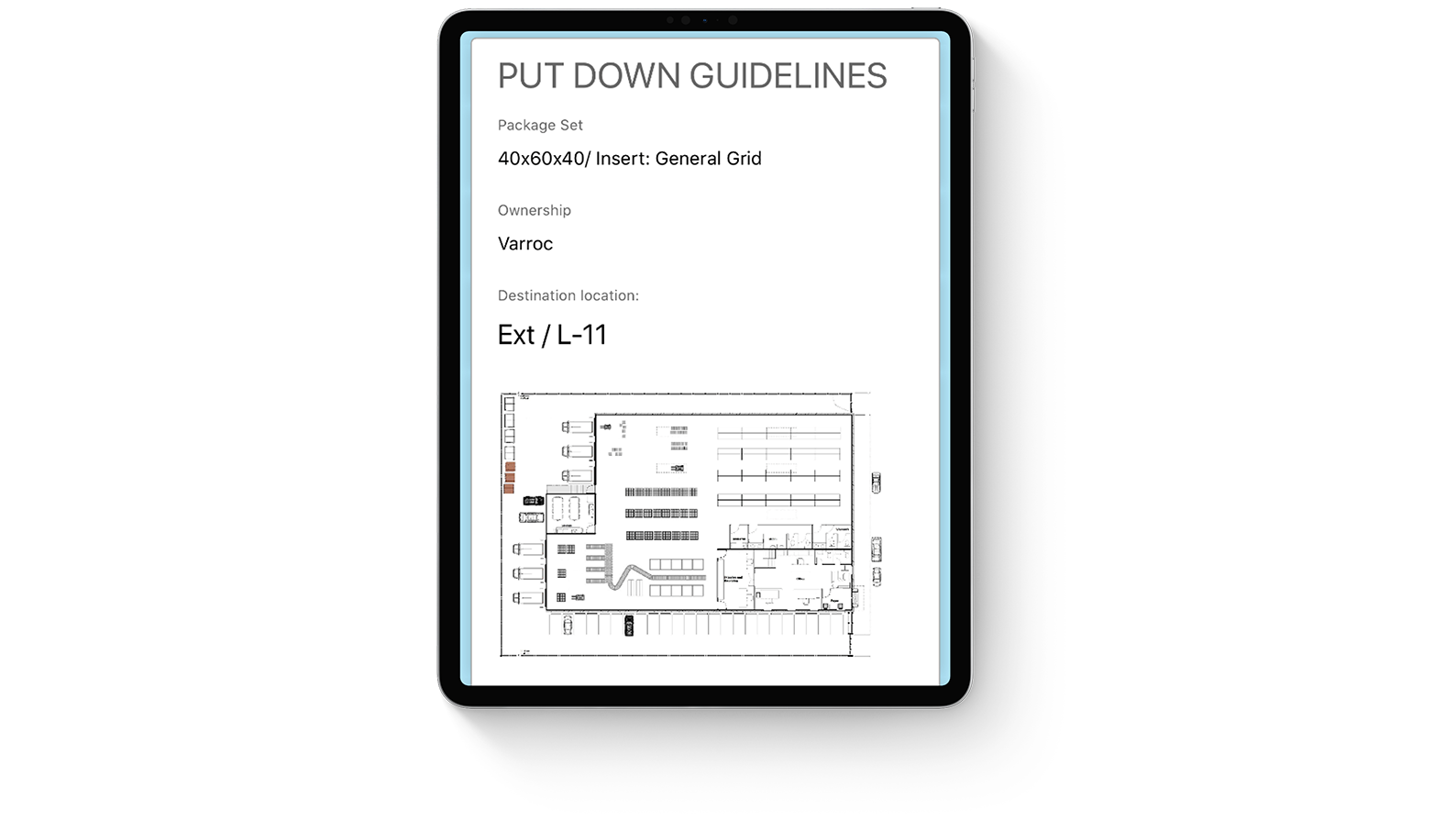

Storing Empty Packaging

Empty packaging doesn’t just sit around—RPMS manages a structured process. Containers first receive a “transitional” status until verified complete. Guided put‑away suggests the correct location, considering container type and ownership. Workers confirm with a barcode/QR scan of the storage zone, ensuring precise traceability of every reusable container.

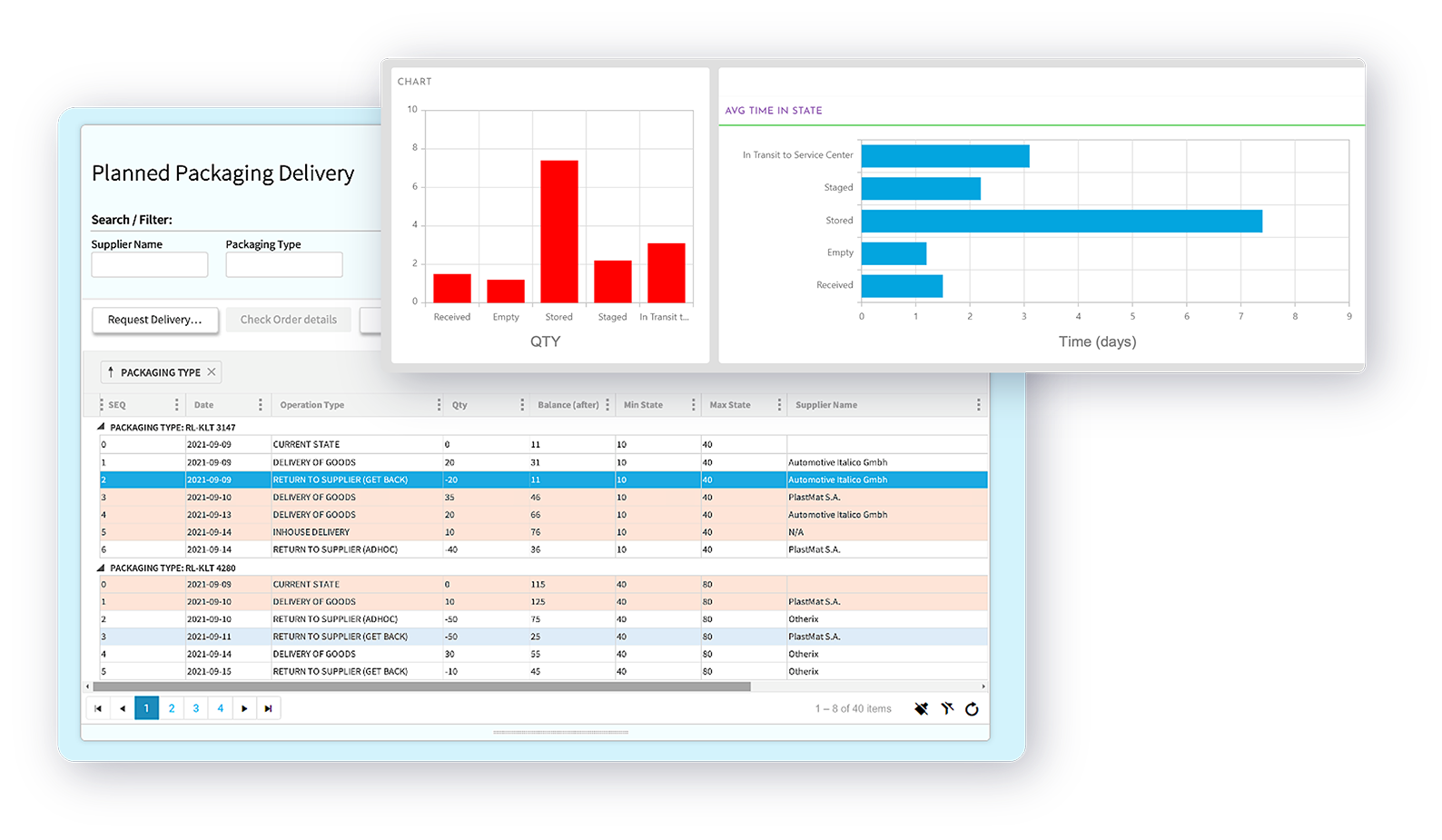

Shipping to Suppliers

RPMS optimizes the return flow of containers to suppliers. Supervisors receive automated reports highlighting excess stocks, preventing last‑minute shortages and costly premium freight. Workers execute guided truck loading with mobile scanners, confirming each container as it is placed on the truck. Any anomalies—missing, damaged, or substituted containers—are logged and resolved immediately.

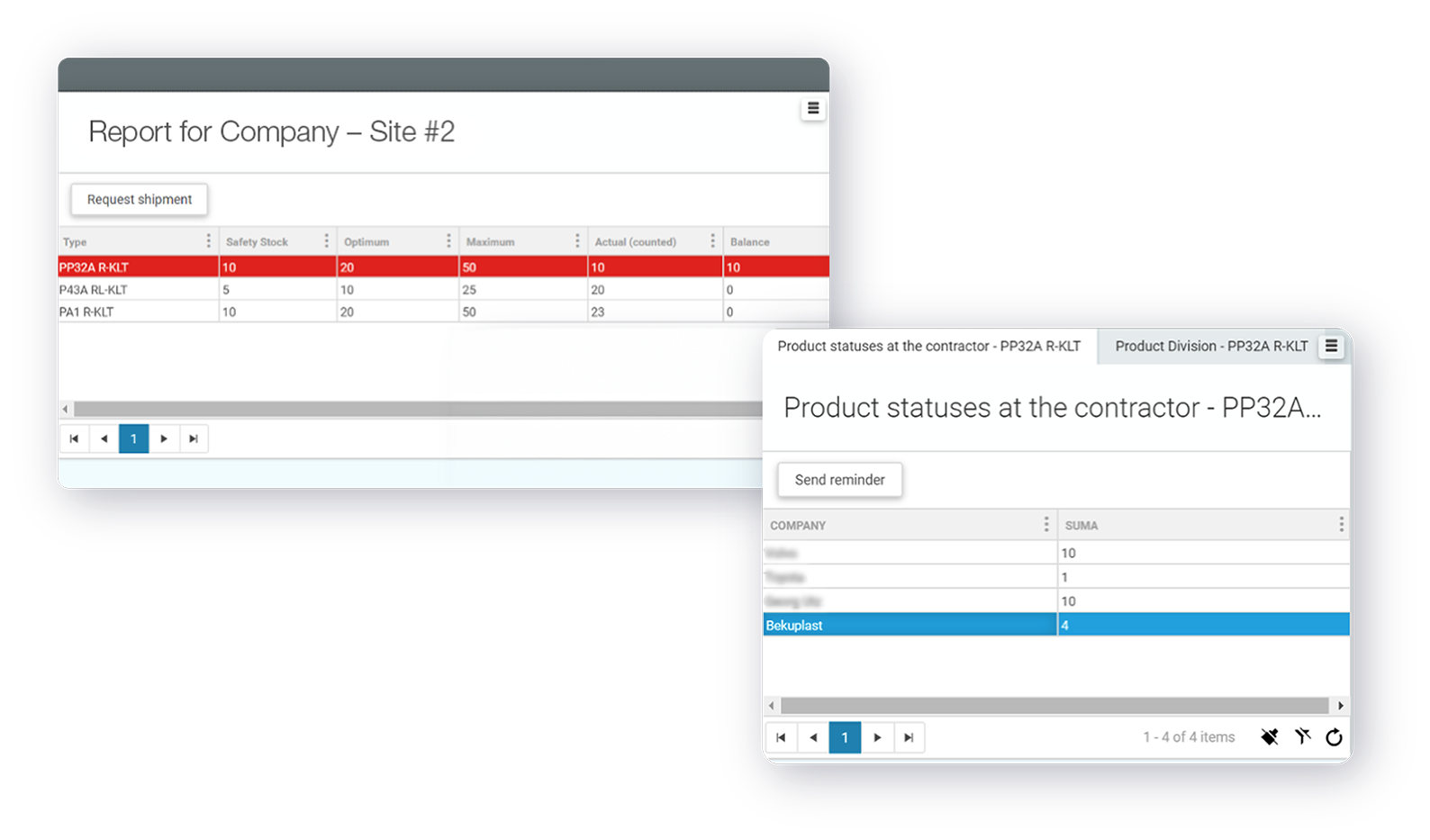

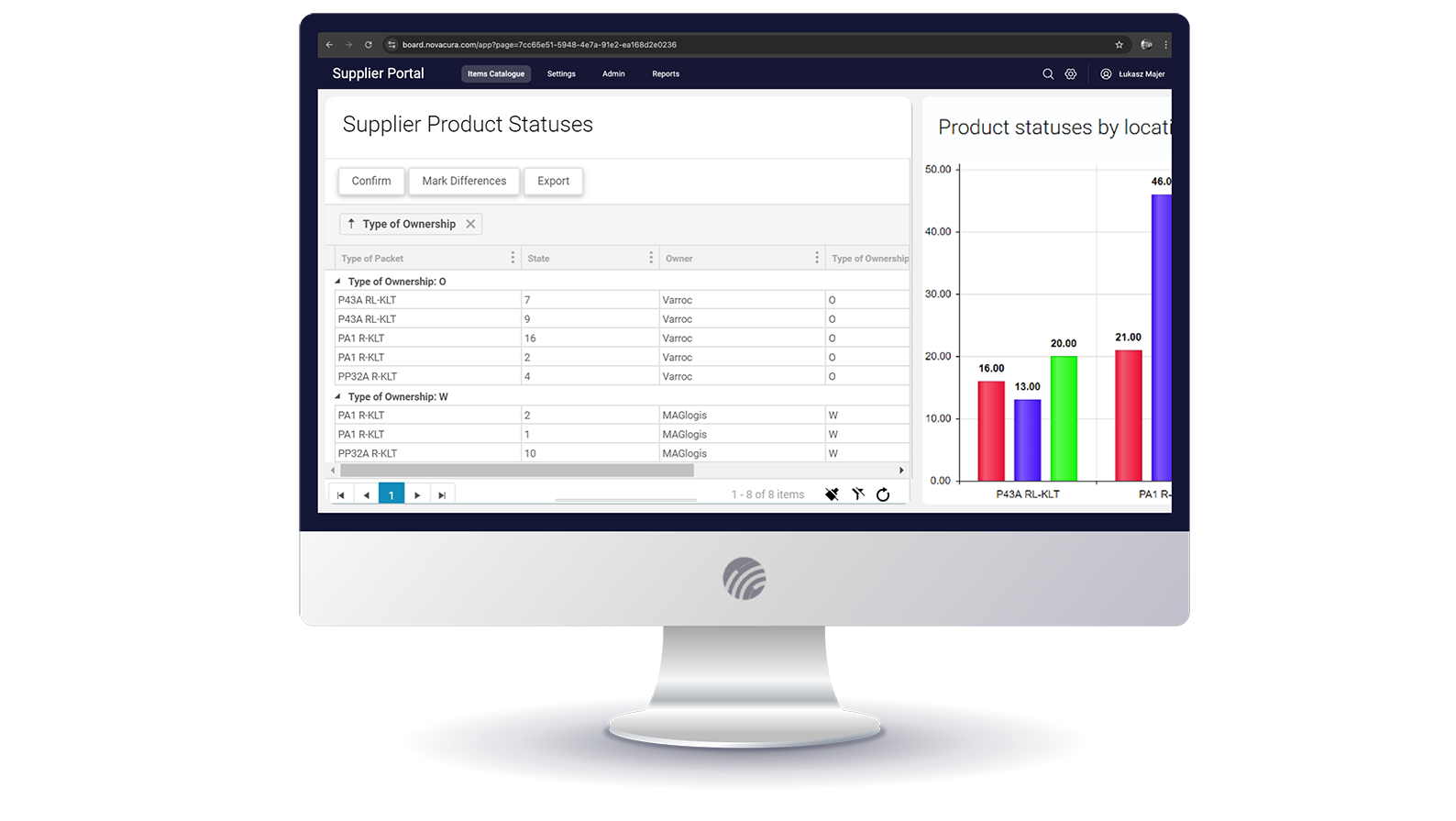

Supplier Portal

Collaboration with suppliers is built‑in. Through the Supplier Portal, partners can confirm receipts of returned containers, declare packaging shipped together with components, and trigger urgent return requests when their stock runs low. This creates transparency in returnable packaging management and reduces disputes around balances and shortages.

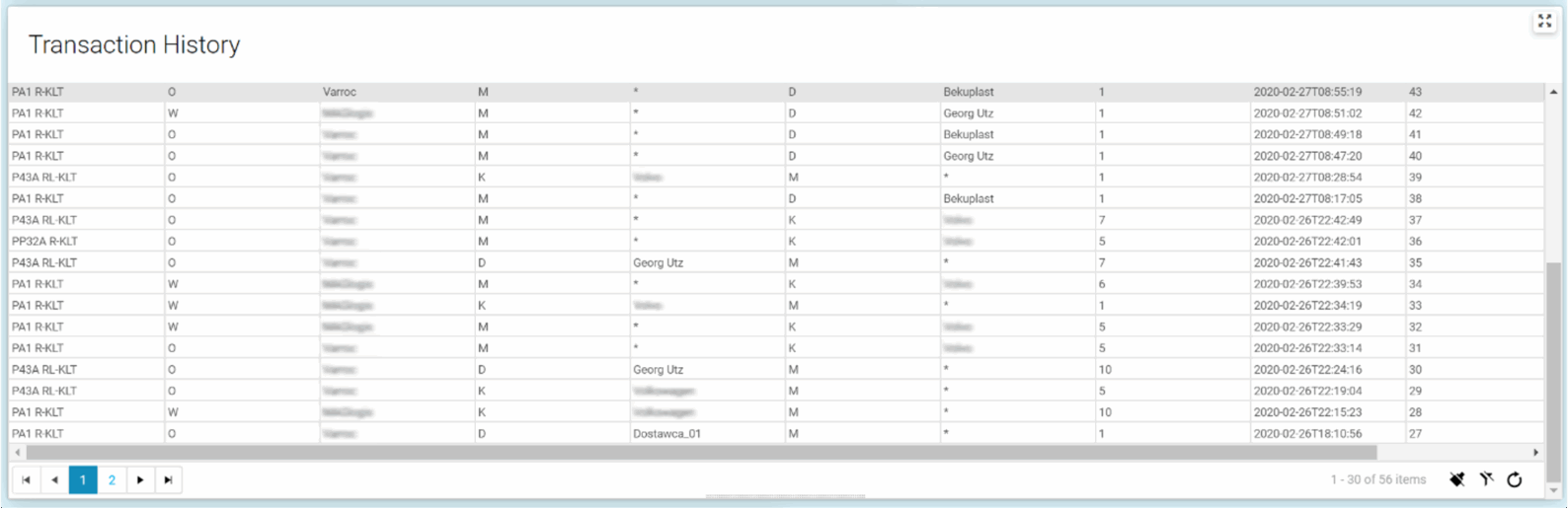

Periodic Balance Reconciliation

RPMS doesn’t only track daily operations—it also keeps long‑term balances correct. Run inventory campaigns by site, supplier, or packaging type, using mobile counting tools with barcode support. Suppliers receive balance sheets for confirmation, with automatic approval after deadlines. This stabilizes returnable containers management even with partners who don’t confirm in real time.

Exception Handling & Verification

Reality isn’t perfect—containers get damaged, incomplete, or misconfigured. RPMS lets workers report issues from mobile devices, including photos and notes. Containers are flagged with colored labels (red, yellow, green) for easy identification. Special workflows assign tasks to admins for resolving discrepancies and updating configuration, keeping master data trustworthy.

Packaging Configuration Management

At the heart of RPMS is a central configuration database. Map packaging sets to specific components with rules on ownership, contract scope, palletization, and substitutes. Anomalies reported by workers trigger review tasks for administrators, ensuring the system reflects real‑world usage in your reusable packaging management.

Packaging Status Tracking

Every container follows a defined lifecycle: with supplier → in transit → at customer site → in production → empty → returned. RPMS records statuses in real time, with special states like “quarantine” and “to‑verify” to manage exceptions—delivering end‑to‑end visibility across the returnable packaging management loop.

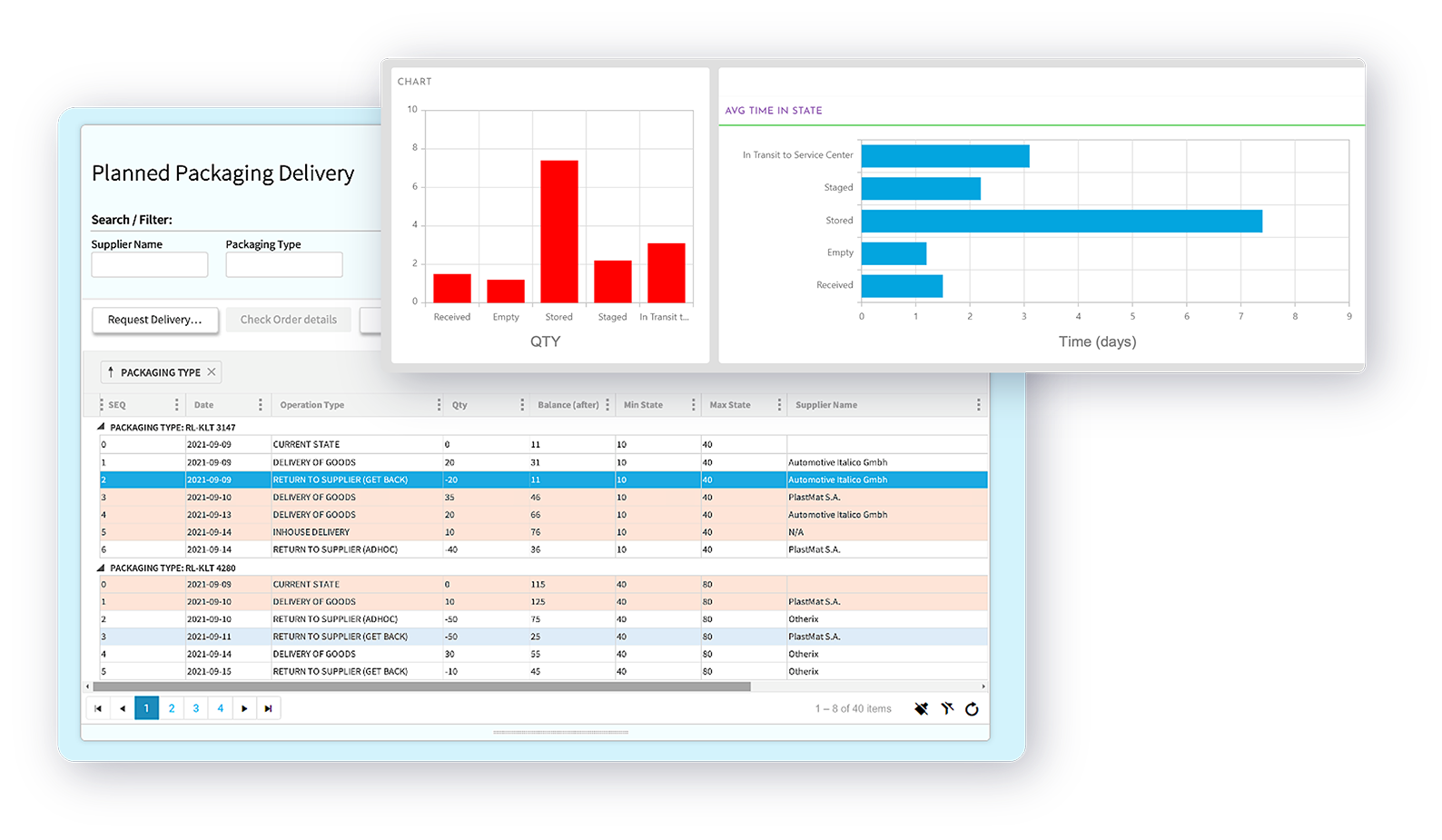

Reporting & Analytics

Logistics managers gain clarity through dashboards. Operational reporting shows current stocks, imbalances, and pending tasks, while management analytics highlight KPIs such as packaging losses, premium freight frequency, and supplier performance. Export to Excel for deeper analysis and governance.

Industries We Serve:

Returnable packaging challenges look different across industries — but the need for control, visibility, and cost reduction is always the same. RPMS helps companies in:

01

Automotive & Component Manufacturers

Track specialized packaging like racks, bins, and dumpers across suppliers and plants. Ensure parts always arrive safely and on time.

02

Window & Glass Producers

Manage reusable racks for large, fragile items. Prevent damage, reduce loss, and keep deliveries running smoothly.

03

Solar Panel Manufacturers

Control returnable racks used in panel transport. Optimize rotations between factories, warehouses, and installation sites.

04

Beverage Producers

Track bottles, crates, and kegs through the full distribution cycle. Eliminate shrinkage and cut replacement costs.

05

Construction Materials & Pallet Distributors

Monitor pallets and containers moving between depots, distributors, and construction sites. Reduce theft, avoid over-purchasing, and keep stock balanced.

Business Benefits:

01

Lower direct costs

02

Reduced risk of production stoppages

03

Lower premium freight expenses

04

Optimized purchasing of packaging

Prevent unnecessary buys by tracking real demand vs. loop balances.

05

Higher logistics efficiency

Eliminate urgent searches, last‑minute transports, and manual reconciliations.

06

Improved supplier relations and corporate image

Fewer errors, transparent balances, professional collaboration.

Complete Feature List:

01

Inbound & Receiving

- Inbound Receiving (with Suppliers): capture packaging alongside deliveries; three input modes: by material, barcode scan, or manual entry; auto-validation vs. configured packaging.

- Ownership Resolution: automatic setting of ownership (supplier / customer / 3rd party) per contract rules; manual override when labels are missing.

- Contract Adherence Check: optional enforcement that packaging is linked to the correct supplier contract (especially when barcodes are used).

- Supplier Shipment Reconciliation: compare supplier-declared packaging (pre-advice) with what’s actually received; workflow tasks for discrepancies.

02

Internal Logistics & Production Support

- Issuing to Production: propose packaging for pick lists from SAP; one-click confirmation by logistics; manual corrections supported.

- On-Line Verification at Issue: enforce verification for “to-verify” sets (yellow/green label cases) before release.

- Returns from Production: workstation + packaging scan; completeness check for sets (box, inserts, lid); damage flagging.

- Empty Packaging Storage: “transitional” status until complete; guided put-away by type/ownership; barcode/QR location confirmation.

03

Supplier Returns & Transport

- Planning Returns to Suppliers: balance/stock report highlights excess by type/supplier; create return tasks directly from the report.

- Truck Loading & Handover: mobile-guided picking and load confirmation by scan or list tick-off; manage shortages, damages, substitutions.

- Premium Freight Tagging: mark urgent shipments; analyze frequency by plant, supplier, initiator.

04

Supplier Collaboration (Supplier Portal)

- Supplier Portal: secure portal for suppliers with limited balance visibility per contract; confirm receipts, declare shipped packaging, raise urgent return requests.

- Excel Import/Export (Supplier & Internal): import shipment/balance lists; export for counting or system uploads; streamline reconciliations.

- Periodic Balance Reconciliation: schedule inventory campaigns by site/type/supplier; mobile counting; automatic cut-off and approval after deadlines; email reminders.

05

Exception Handling & Master Data

- Exception Handling: report damages, incomplete or misconfigured sets with photos; color labels (red/yellow/green); quarantine status; auto-tasks for admins.

- Configuration & Master Data: central mapping of sets to components; substitutes; palletization rules; max quantities; pictures; ownership and contract rules.

- Status Model: lifecycle tracking (with supplier → in transit → at CUSTOMER → in production → empty → returned); special states (quarantined, to-verify).

06

Technology & Analytics

- Operational Reporting: live dashboards for warehouse supervisors—stock by type/owner, in-transit vs. on-hand, exceptions, pending return tasks.

- Management Analytics: KPIs on premium freight, packaging losses, supplier performance, reconciliation timeliness.

- ERP Integration (SAP): consume purchase deliveries and production pick lists; use ERP IDs for validation and reconciliation.

- Barcode-Ready, Barcode-Optional: supports labeled flows for maximum efficiency and unlabeled flows when labels are not yet implemented.

- Multi-Site & External Warehouses: same processes for internal plants and external DHL sites; separated locations and statuses.

- Mobile Apps for Logistics: scanner-friendly UIs for receiving, issue, returns, put-away, loading, counting, exception reporting.

- Tasks & Workflows: automatic tasking for discrepancies, configuration fixes, supplier disputes, verification steps.

- Auditability & Traceability: quantity-level balance and status tracking; optional tighter traceability at set-level with barcodes.

FLEXIBLE TECHNOLOGY BEHIND OUR RPMS PACKAGE:

ERP extensions that are fast to implement

Our Novacura RPMS Package is built on a strong foundation: it must be easy and fast to implement! We created it as a package of ERP extensions that are dedicated to working with the most popular ERPs (such as IFS, Infor, SAP). With that approach, you can turn them on and start using them. The ERP integration (that is usually the most complicated part) is prepared “out-of-the-box”.

The true benefit of the ERP extensions philosophy is that when you implement these applications, it doesn’t affect surrounding ERP processes – all ERP users will still see all operations (performed in Novacura) in the ERP, as they used to see them before!

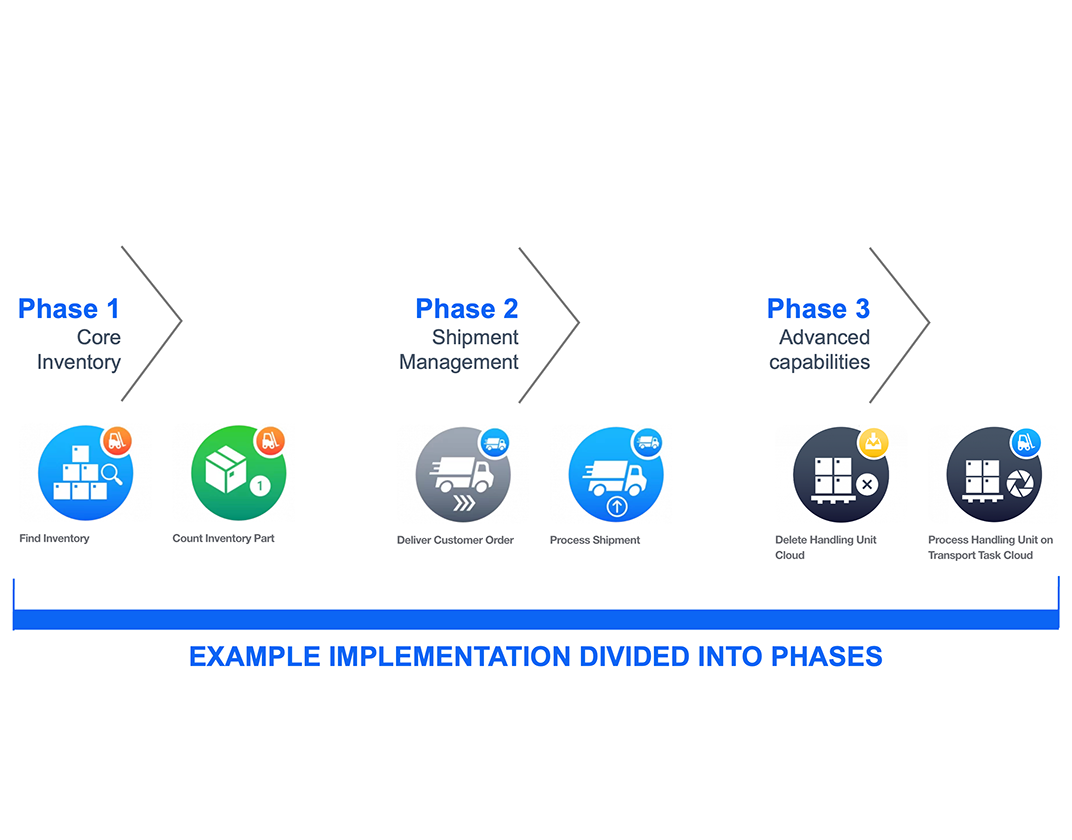

An iterative approach, no revolution needed

Novacura RPMS solution offers various applications to support and optimize operations. As these apps are prepared as ERP extensions, they share the same source of information: the ERP database. As a result, you don’t have to implement all of them at once. If you don’t want to implement some applications in the 1st phase, the standard ERP functionality will still be used instead of them. So you can add them later when the first package of process changes is adopted by your organization. That makes it ideal if you’re comparing types of returnable packaging management systems or need to start small and scale later.

Ready for future changes thanks to the low-code core!

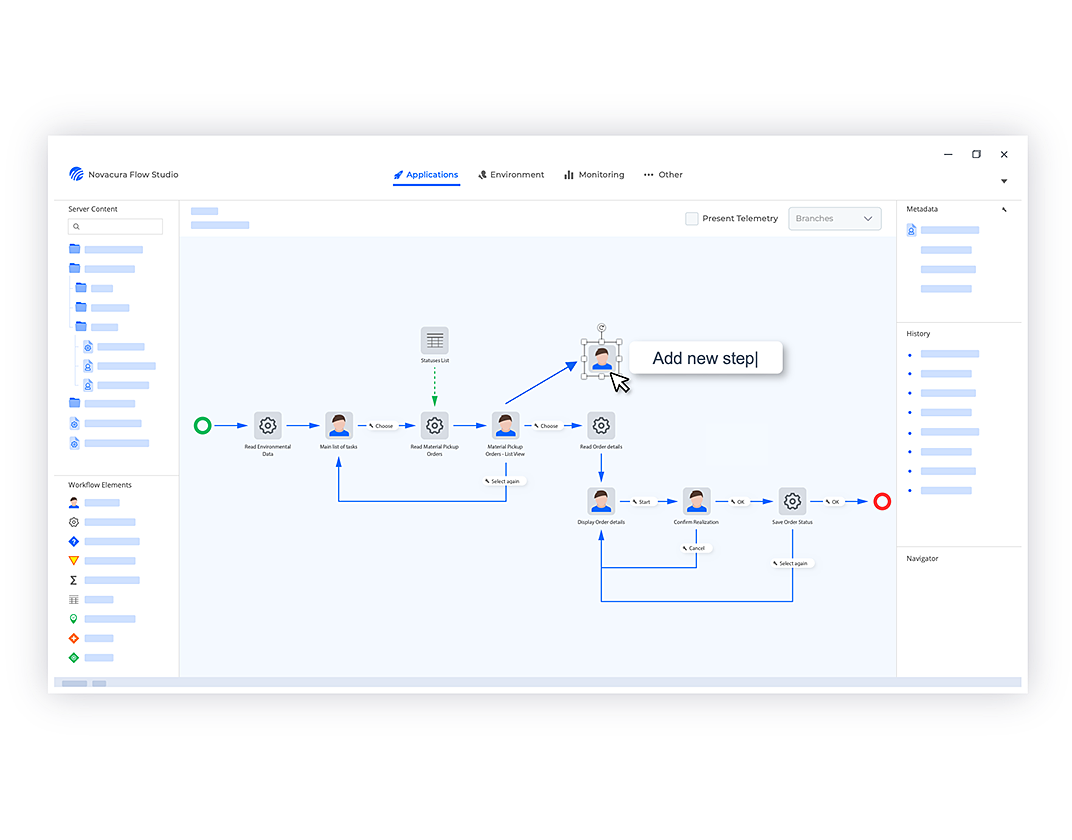

Every company is different from the others. You might have specific processes and require unique features, and we are ready for that! Our RPMS Package is based on the low-code platform Novacura Flow. It means that all our applications are not hard-coded. Our customers can modify them or clone them and create variants. And they can build their own applications. And thanks to the low-code engine, they can create apps by drawing them like they draw a business process. This approach effectively gives you a warehouse management platform you can tailor without code-heavy projects. Teams can spin up custom software modules to match new workflows, regulatory changes, or site-specific needs.

The Simplified Implementation Process:

The implementation process takes less time than usual. We have a flexible solution that can be easily integrated with existing systems.

1. Mature methodology

We have a mature implementation methodology divided into stages (like initial requirements workshop, feasibility study, etc.) — that way the whole project is predictable and can be fully controlled and coordinated by us.

2. Years of experience

We have 17+ years of experience in logistics. There is a library of ready-to-use applications that can be

presented to the customer and customized according to his needs. And the library is available on the Novacura Flow Marketplace.

3. Low-code platform

Novacura Flow is a low-code platform – so we can implement everything our customer wants, and every element can be adjusted to specific customers’ needs.

4. Industrial connectors

We have a solid base of industrial connectors – the technology is no longer a problem.

Contact Us:

Please fill out the form. Our team will respond within 1 business day.

Prefer email? Contact us here: info@novacura.com