- Home|

- MES Software

Manufacturing Execution System (Light MES)

Solution for IFS and Infor M3

Real-Time Production Tracking

Material Consumption Reporting

Mobile Operator Interface

Bottleneck Analysis

Machine Connectivity

ERP Integration

Our MES solution captures data directly at the source, enforces standard work and quality checks, tracks WIP and product genealogy, and provides live KPIs such as OEE and throughput. By connecting seamlessly with ERP systems like IFS and Infor M3, as well as with automation platforms (PLC, SCADA, IIoT), Novacura MES synchronizes schedules and inventory, minimizes downtime, shortens lead times, and delivers full traceability from raw material to shipment.

Who Benefits from MES:

Our Manufacturing Execution System gives every role — from planners to operators — real-time visibility and control of production. It connects people, machines, and materials to ensure accuracy, efficiency, and continuous improvement.

01

Site Managers

Gain full visibility of production progress and ensure materials, machines, and staff stay in sync.

02

Production Planners & Engineers

See real-time data on work center performance, actual material usage, and scrap levels for better planning.

03

Continuous Improvement Managers

Access live process data to identify bottlenecks and optimize workflows with confidence.

04

Logistics Teams

Track real-time material consumption on the line and supply materials just-in-time.

05

Maintenance Teams

Get instant notifications when production stops, thanks to direct connectivity with machines.

06

IT & ERP Owners

Extend ERP beyond its limits with a fully mobile, customizable MES — integrated without modifications.

MES Solution Capabilities:

01. Schedule deliveries

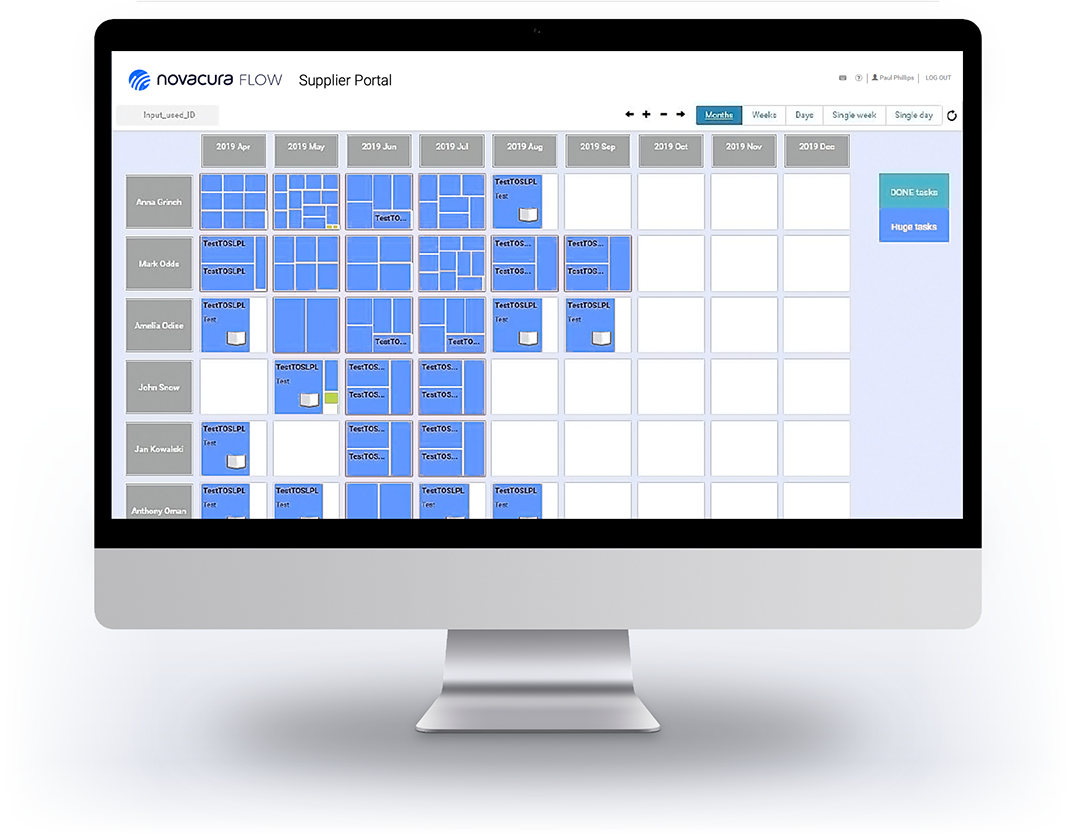

With Novacura Flow’s manufacturing execution system (MES) solution, you can plan material requisitions based on production orders and current stock levels. Using the integrated B2B Portal, suppliers confirm delivery schedules and book unloading time slots—ensuring a smooth material flow from planning to production.

02. Connect internal logistics with the shop floor

Your internal logistics team can use the same mobile MES application as shop floor operators. All material delivery requests, returns, and packaging movements are instantly visible, and production orders update in real time as soon as logistics confirm delivery. These manufacturing execution system functions eliminate delays and keep production synchronized.

03. Optimize picking paths

Picking across large warehouses can be complex, but Novacura Flow’s MES includes a mobile WMS that optimizes routes based on location, weight, unloading sequence, or expiration dates. Operators use barcode scanners for accuracy and speed. These manufacturing execution system features for JIT environments reduce wasted time, lower costs, and improve picking efficiency.

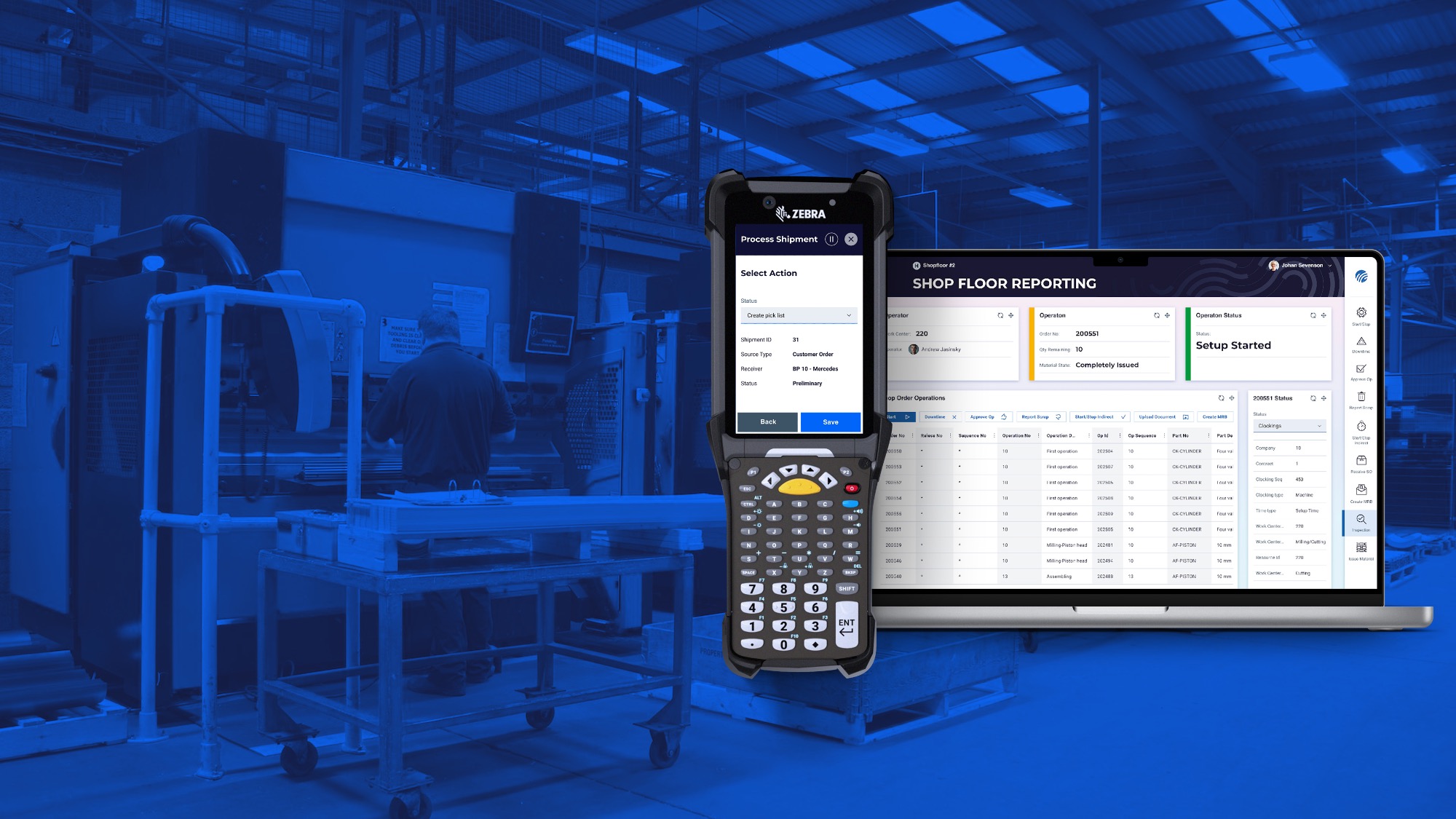

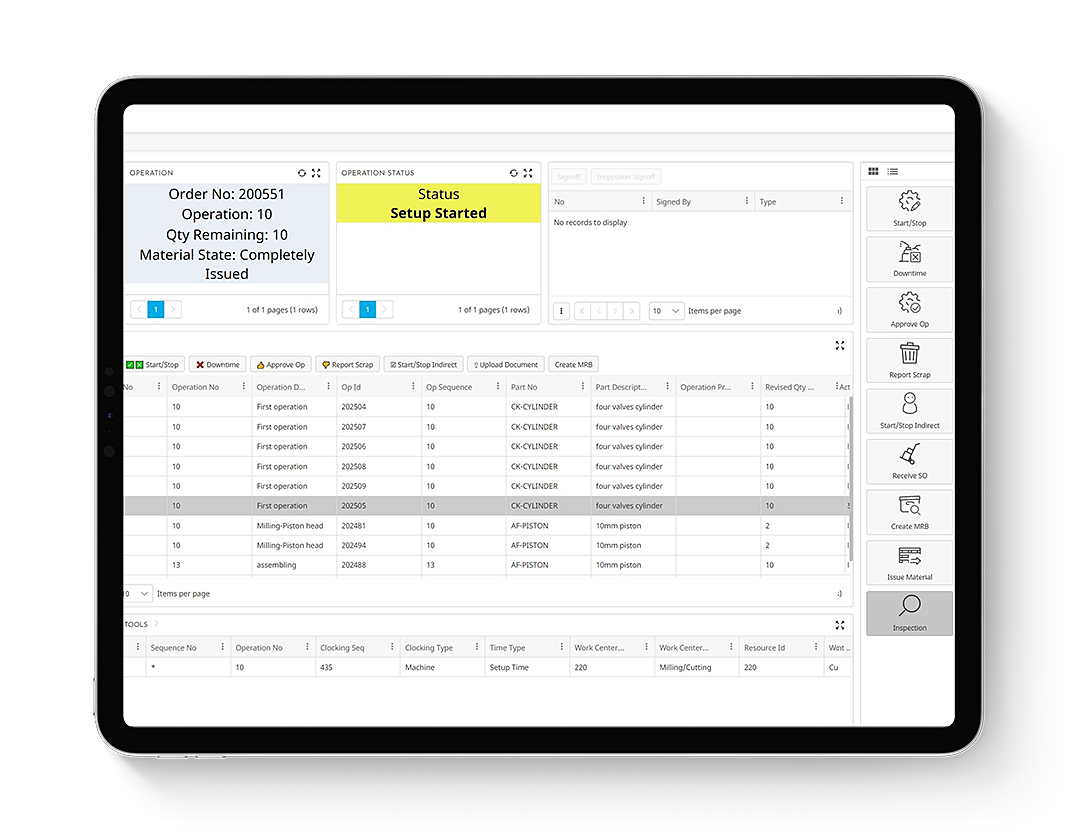

04. Work mobile and report every operation

Operators use a mobile MES application to view updated work orders, log activities, request materials, report downtime, or call for maintenance. Information flows directly into IFS or Infor M3, giving managers real-time visibility. This manufacturing execution system advantage helps managers react quickly, optimize OEE, and ensure continuous improvement.

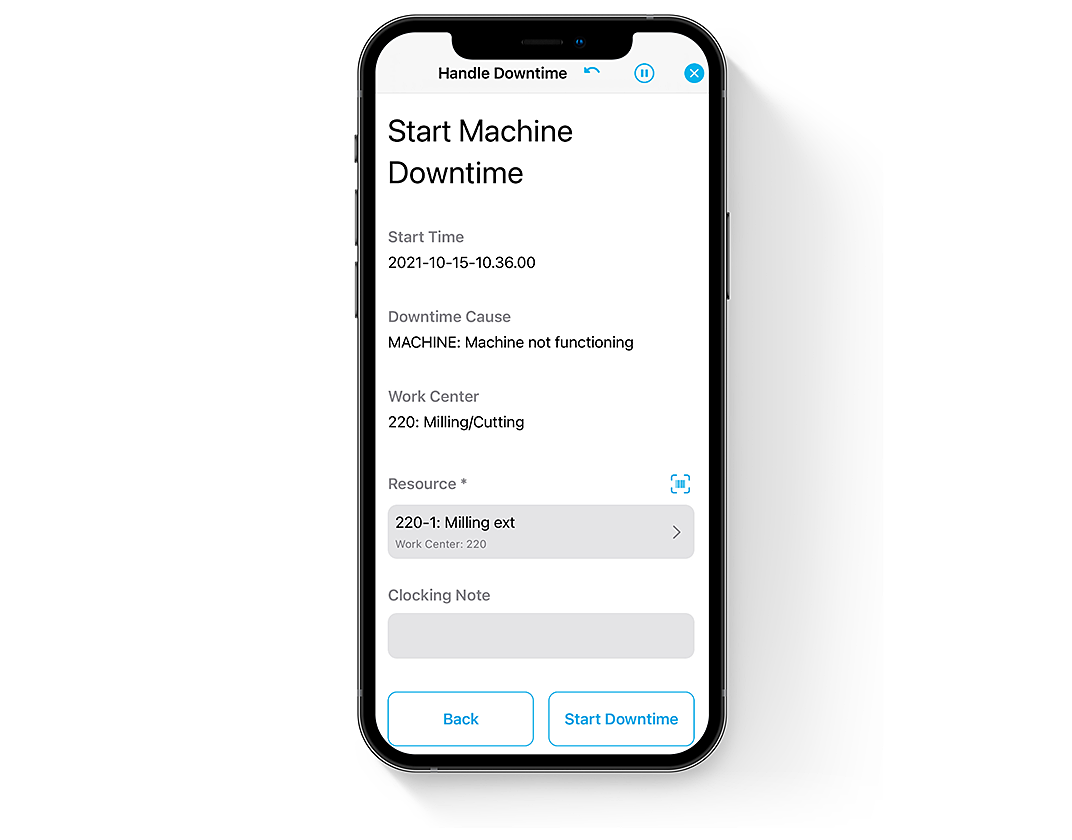

05. Incorporate maintenance and reduce downtime

In Novacura Flow, production and maintenance operate within one MES environment. Maintenance teams receive automatic notifications when downtime is detected, allowing them to act before production is disrupted. This tight integration is one of the key manufacturing execution system advantages, reducing MTTR and improving overall equipment availability.

06. Track actual data & optimize the entire process

With Novacura MES Solution, production efficiency can be precisely measured. Data is gathered directly at the source—from mobile applications used by operators to signals coming from connected devices.

It includes industrial connectors (BLE, OPC-UA, PLC, RFID) that enable seamless integration with machines and other systems. These integrations follow manufacturing execution system standards for reliable, real-time data capture and analytics, giving managers full visibility across the entire production process and enabling continuous optimization.

And a lot more…

Let us show you our complete package of applications dedicated to supporting manufacturing companies!

“The stockroom group saves time and steps, which is good for flexible processes. But above all, we see that discrepancies and returns are going down – we simply have more satisfied customers now”

Matt Hanson

Business Analyst, Minco

OUR CUSTOMERS:

“Thanks to this solution, warehouse workers have increased their efficiency by about 30 percent, and the error rate has dropped radically.”

Leif Repo

Group Logistics Manager

Specma AB

"I really like Novacura Flow because of its flexibility. From a software engineering perspective, the flow and processes can easily be visualized and modified."

Mario Bischofberger

Lean Manager Logistics

Maxon

“Implementing Novacura Flow would save 250 working days, it means a saving of €80 000 per year."

Arjen Hoefkens

Solutions Manager

Heerema Group (HFG)

“Sherwin-Williams has advanced product flows, and creating a solution that included everything while still being simple and user-friendly was a real challenge."

Sabina Wenker

Manager Distribution Center

Sherwin-Williams

Industries We Serve:

01

Furniture Manufacturing

Track material consumption and production steps for custom and made-to-order products.

02

Pharmaceuticals

Ensure traceability, compliance, and real-time process control in regulated environments.

03

Maritime & Offshore

Manage complex, long-cycle production like ships, oil rigs, and marine equipment.

04

Industrial Parts & Components

Monitor production of screws, springs, and custom components with detailed reporting.

05

Raw Material Producers

Get accurate tracking of heavy, process-driven production flows.

List of supported areas:

Novacura Flow provides a wide range of mobile applications that extend the capabilities of a Manufacturing Execution System (MES) for manufacturing companies. These applications help integrate shop floor operations with ERP systems such as IFS and Infor M3, ensuring efficiency and visibility across the entire production process.

01

Maintenance

- Maintenance tasks planning – Integration with production plans

- Mobile Work orders for maintenance (preventive & reactive)

- Tools management

- Spare parts management

- Maintenance subcontractors management (incl. financial settlements)

02

Shop floor operations

- Mobile shop orders processing

- Reporting (Time, Material, Scrap etc.)

- Logistics requests (material requisitions, returns, package requisitions)

- Downtime reporting

- Defects reporting

- Maintenance calls

- Staff management

03

Internal logistics

- Material delivery (JIT, up to particular production sequence)

- Different picking strategies support (FIFO, FEFO, LIFO)

- Warehouse <> Shop floor transportation management

- External inventory usage optimization

- Material returns management (from production)

- Finished goods transportation

04

Inventory operations

- Material storage (material moves, handling unit management, traceability)

- On-the-fly Inventory counting support

- Picking paths optimization

- Outdated materials / Scrap management

- Barcode labels management

- Full support for barcode scanners

05

Production planning / Scheduling

- Long Term planning (S&OP, Demand, Master etc.)

- Short Term planning (Capacity, Material)

- Repeatable / discrete production support (BOM based)

- Contractual production support (configure to order based)

- Daily Plans updating based on real execution

06

Delivery & Shipment management

- Stock level management based on production plans

- Delivery planning & management

- Financial settlements with suppliers and customers

- Finished goods inventory management

- Shipment planning

- Transportation management

- Returnable packaging management

07

Automation / Technology

- Industrial IoT (IIoT) / Industry 4.0 support

- Connectivity (OPC-UA, PLC, RFID / BLE)

- Integration between machines and ERP – real performance statistics processing

- Support for various ERPs (IFS, Infor M3, IBM Maximo, SAP and more)

- Computer Vision

- Augmented Reality based support

08

Production supervision

- KPI Dashboards

- Visual “Info-Screen” on a Shop floor

- OEE evaluation

- Defects analysis / traceability

- Supplier stats analysis

- Material usage analysis (performance vs technology)

- Continuous improvement support (thanks to the low-code process modeling technology)

Manufacturing Execution System (MES) Benefits with Novacura Flow:

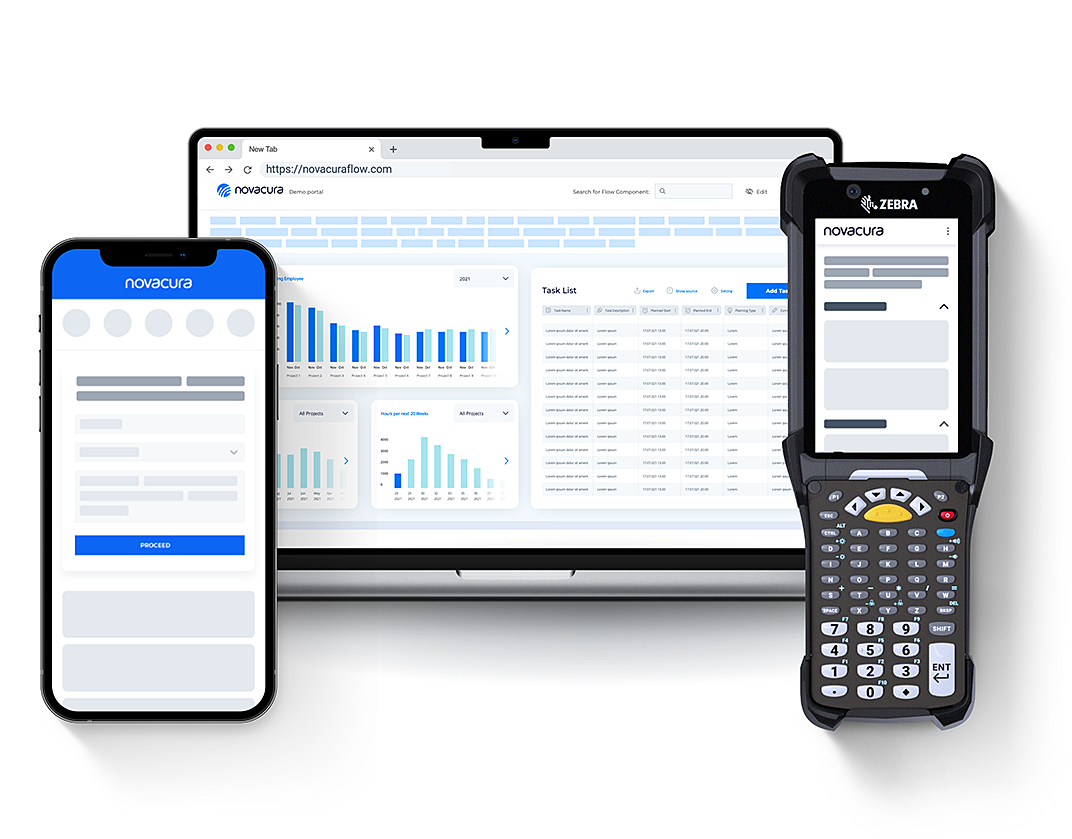

Interface optimized for thousands of operations per day

Our MES applications, built on Novacura Flow, are designed to run seamlessly on any device—barcode scanners, mobile phones, tablets, or desktop workstations with large screens. The interface is optimized for shop floor and warehouse operators, where every click matters. In high-volume environments, this level of ergonomics is essential in manufacturing execution system (MES) manufacturing, ensuring both speed and accuracy directly translate into higher throughput.

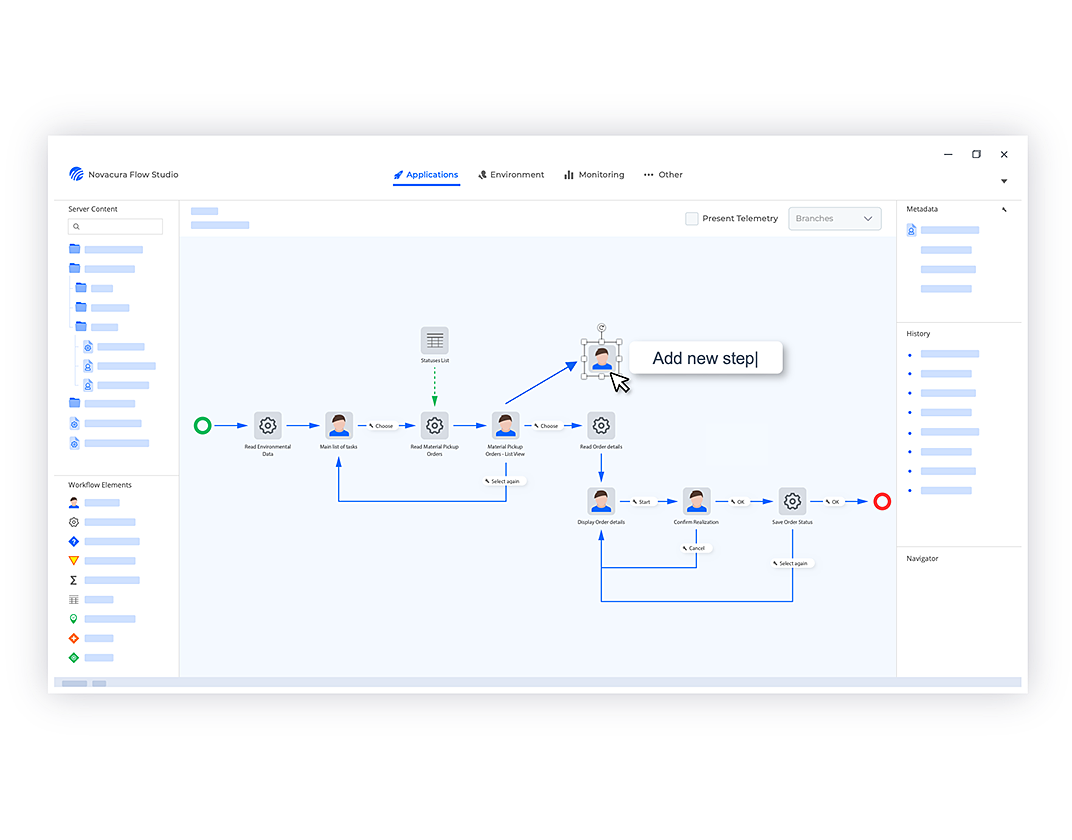

Ready for changes thanks to its low-code core!

Every manufacturing company has unique processes, and Novacura Flow adapts to them. Our MES solution is built on a low-code platform, meaning applications are not hard-coded: customers can easily modify, extend, or create new variants themselves. With the low-code engine, applications can be drawn like a business process, enabling rapid adaptation. This flexibility means Novacura’s manufacturing execution system software can be tailored quickly and scaled as requirements evolve—supporting both continuous improvement and long-term growth.

Integration with ERP. Deep integration!

Novacura Flow is a low-code platform designed to work hand-in-hand with your ERP system. While our MES applications handle shop floor operations, we treat ERP (such as IFS or Infor M3) as the primary system where all master data, transactions, and reports are stored. Everything done in Novacura Flow is immediately visible in ERP—thanks to specialized online connectors.

With Novacura Flow, you can think of it as an alternative, mobile, and efficient user interface for ERP. This makes it easy to adopt MES functionality without disrupting your existing ERP processes. Our bidirectional, real-time ERP connectivity is foundational to MES, ensuring that schedules, production data, and reporting stay fully synchronized.

THE PROCESS IS SEAMLESS AND RISK-FREE:

The implementation process takes less time than usual. We have a solution that can be easily integrated with existing systems.

1. Mature methodology

A structured implementation methodology, divided into stages like initial requirements workshops and feasibility studies, ensures predictability and control. This approach helps businesses efficiently plan projects while understanding the cost of manufacturing software.

2. Years of experience

We have 17+ years of experience in Manufacturing. We have a library of ready-to-use applications which can be customized to business needs. Our library is available in the Novacura Flow Marketplace.

3. Low-code platform

The Novacura Flow platform offers low-code flexibility, enabling rapid implementation and full customization. Every feature can be adjusted to meet specific requirements, making it a perfect fit for modern manufacturing environments.

4. Industrial connectors

A robust set of industrial connectors ensures seamless integration with ERP systems and other technologies. This eliminates connectivity challenges while optimizing manufacturing operations.

Contact Us:

Please fill out the form. Our team will respond within 1 business day.

Prefer email? Contact us here: info@novacura.com