August 7, 2025

August 7, 2025  15 min to read

15 min to read Artificial intelligence is becoming an increasingly integrated part of modern ERP systems. Within IFS Cloud, IFS.ai offers a built-in suite of AI capabilities designed to support data analysis, automate workflows, and enable real-time decision-making. These features are embedded directly into the platform and available out of the box.

This article takes a closer look at how IFS.ai contributes to operational efficiency within ERP environments. It also explores how low-code tools like Novacura Flow can extend and adapt these AI-driven capabilities to better fit the unique needs of different organizations.

Understanding the Power of IFS.ai: Intelligent Decisions, Streamlined Operations

IFS.ai is engineered to revolutionize business operations by offering a comprehensive suite of AI-driven features that enhance decision-making and optimize various functions. Here’s a closer look at its transformative capabilities:

-

Optimized Efficiency: IFS.ai improves process efficiency and resource utilization, automating routine tasks and minimizing manual intervention. This leads to greater operational efficiency, freeing your workforce to focus on strategic initiatives.

-

Ease of Implementation and Operation: A key advantage of IFS.ai is its embedded nature within the IFS Cloud, meaning it’s not a separate add-on but an integral part of the system. This “embedded, not bolted-on” approach simplifies deployment and reduces implementation complexities. Furthermore, the intuitive design, especially with features like the IFS.ai Copilot, makes it highly user-friendly. Employees can leverage AI-powered insights and tools without requiring extensive technical expertise, fostering rapid adoption and ensuring that the benefits of AI are accessible across all levels of the organization. Companies can explore and scale AI capabilities with clear value, without long lead times or complex implementations, enabling immediate and measurable results.

-

Intelligent Decision-Making: By leveraging AI, IFS.ai transforms raw data into actionable insights across strategic, tactical, and operational levels. It supports enhanced decision-making through features like predictive maintenance in Enterprise Asset Management (EAM), intelligent financial management with AI-powered forecasting, and streamlined HR processes with AI-powered competency recommendations.

-

Enhanced User Experience: The IFS.ai Copilot, a pivotal feature, offers AI-assisted guidance and timely knowledge, significantly improving decision-making and overall user experience. It can surface critical insights across the organization, assisting various roles from service leaders to production managers.

-

Industry-Specific Applications: IFS.ai is embedded across key modules and tailored for specific industries, ensuring that the AI capabilities are highly relevant and impactful to diverse business needs.

IFS.ai Integrations Across Key Modules and Capabilities

IFS.ai delivers Artificial Intelligence across virtually all IFS Cloud capabilities, rather than being confined to specific, isolated modules. This pervasive integration means AI enhances functionality across:

-

Enterprise Asset Management (EAM): Predictive maintenance, anomaly detection, FMECA (Failure Modes, Effects, Criticality Analysis) assistance.

-

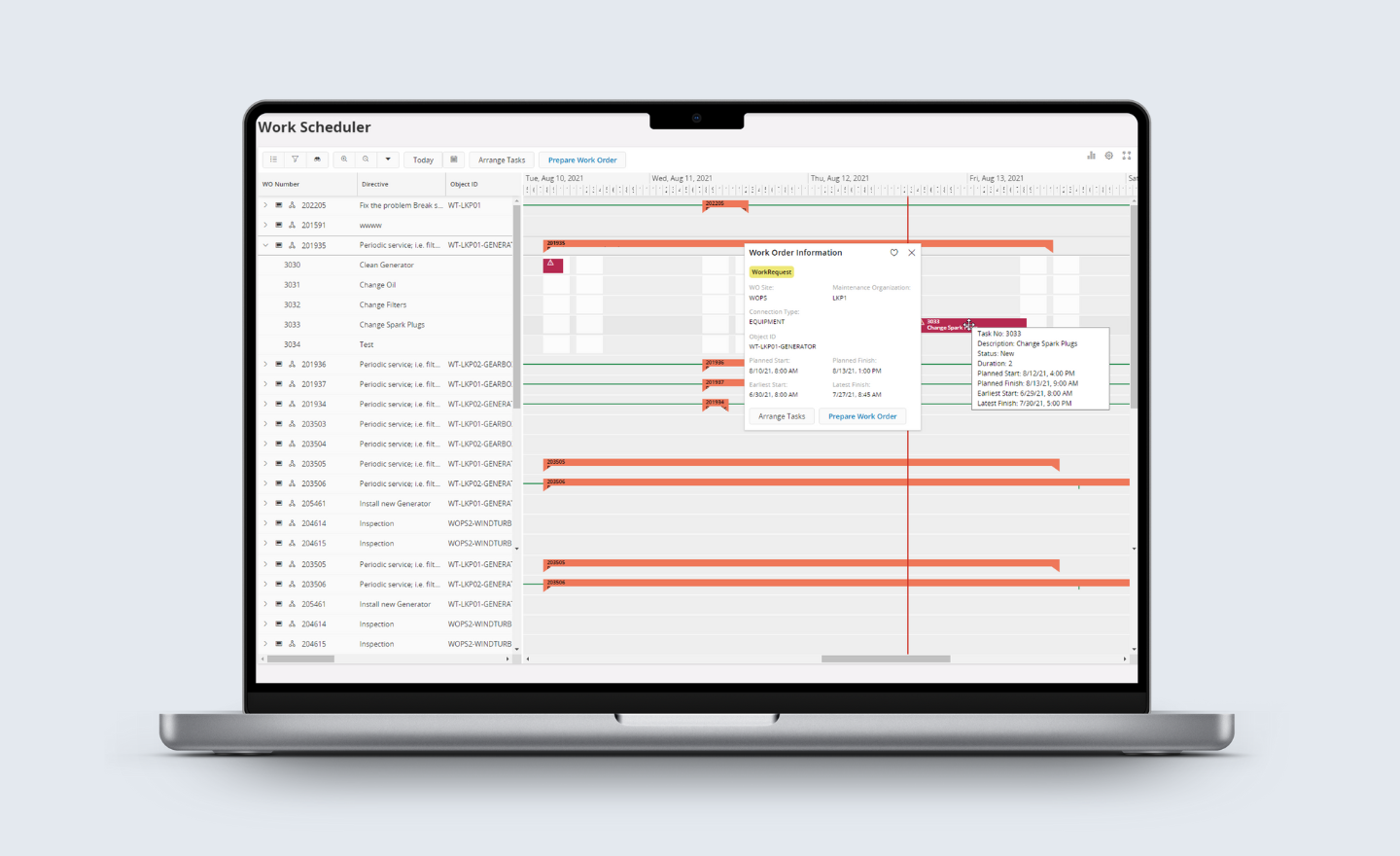

Field Service Management (FSM): Optimized scheduling, intelligent dispatch, service request routing, technician support.

-

Manufacturing: Production scheduling optimization (MSO), demand planning, quality control, automated data capture from shop floor.

-

Supply Chain Management: Inventory optimization, demand forecasting, logistics and transport planning.

-

Finance: AI-powered forecasting, automated invoice processing, intelligent payment allocation.

-

Human Capital Management (HCM): Competency and certificate recommendations, time management assistance.

-

Projects: Project scheduling, risk assessment, resource allocation.

-

Procurement: Supplier performance analysis, spend optimization.

-

Sales & CRM: Sales quotation assistance, lead scoring.

-

Sustainability Management: Emissions tracking and reporting (Scopes 1, 2, and 3), support for circular manufacturing.

Examples of IFS.ai in Action

-

Offshore Drilling: A leading offshore drilling company is transforming its operations by leveraging IFS.ai within the IFS Cloud ERP platform. Facing the challenges of managing immense volumes of operational data, outdated maintenance practices, and the need to ensure uptime for critical safety infrastructure, the company turned to IFS.ai to modernize and optimize its approach.

IFS.ai solves several key problems:

-

Unbiased anomaly detection: Automates the analysis of petabyte-scale data, removing human bias and surfacing hidden failure patterns that would be difficult or impossible to detect manually.

-

Predictive maintenance: Enables a shift from reactive and scheduled maintenance to predictive and prescriptive models, significantly reducing downtime and extending asset lifespans.

-

Automated FMECA: Streamlines the traditionally manual Failure Modes, Effects and Criticality Analysis process, generating insights and maintenance actions autonomously for lower-risk assets.

-

Safe autonomous operations: Supports maintenance automation based on confidence levels and transparent AI reasoning, enabling informed human oversight where needed.

-

Cost and efficiency gains: Reduces unnecessary inspections and maintenance interventions, freeing up engineering resources and minimizing costly production interruptions.

By embedding IFS.ai into daily operations, this offshore drilling company is laying the foundation for a more intelligent, efficient, and autonomous future—where maintenance is driven by insight, not routine.

-

-

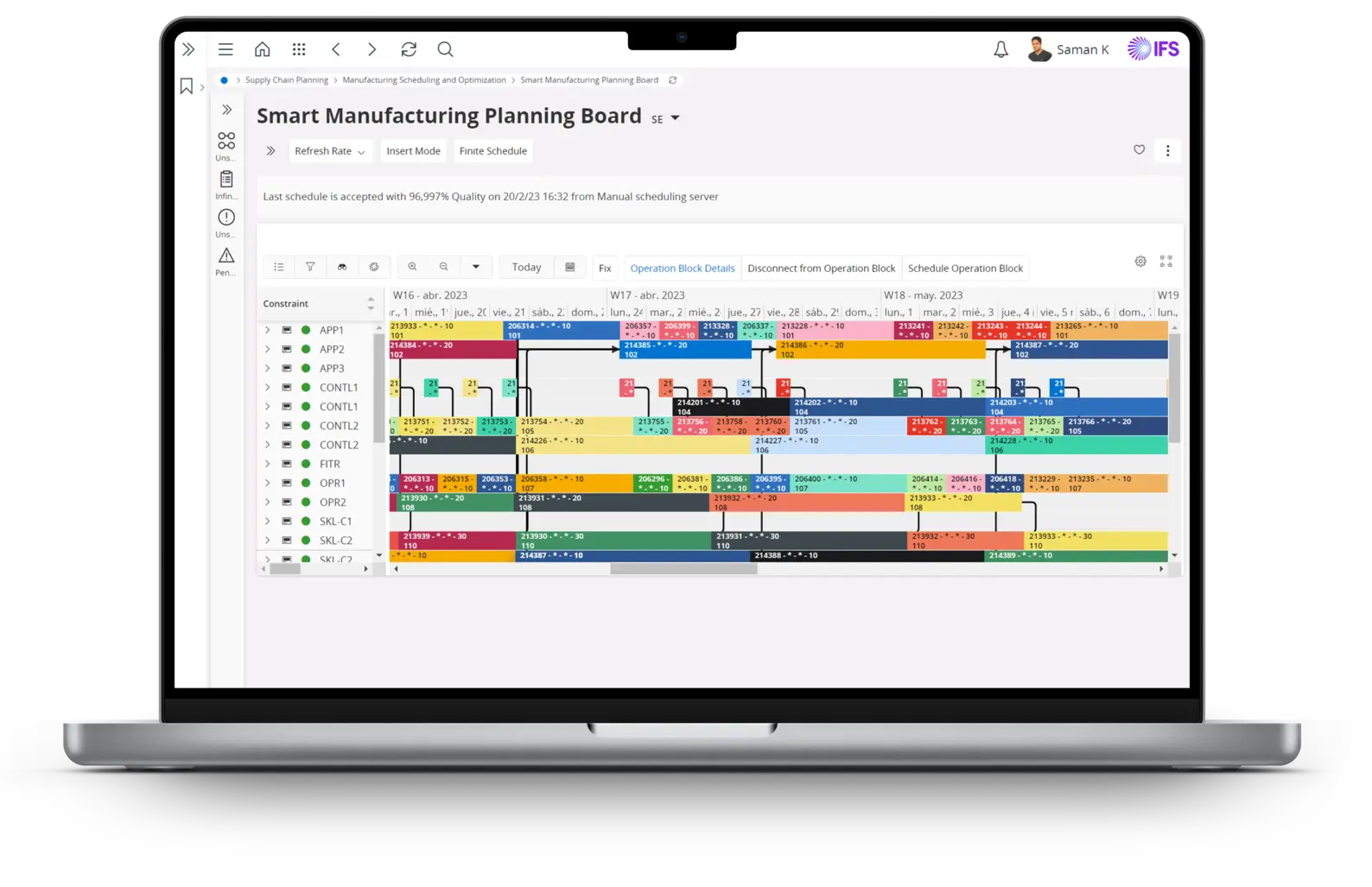

Industrial Automation/Order Processing: A European manufacturing group has adopted IFS.ai to drive greater efficiency and agility in its production operations. Facing the need to optimize resource utilization and respond swiftly to external disruptions, the company implemented IFS.ai’s Manufacturing Scheduling and Optimization (MSO) capabilities.

IFS.ai addresses key challenges in manufacturing:

-

Automated production planning: Eliminates manual scheduling processes, reducing time and effort while improving accuracy.

-

Responsive to change: Uses AI to adapt schedules in real time based on supply chain fluctuations, demand shifts, or production constraints.

-

Optimized resource utilization: Ensures critical manufacturing assets are used efficiently, minimizing downtime and bottlenecks.

-

Improved customer outcomes: Aligns production capacity with customer demand, helping planners consistently deliver on expectations.

By integrating IFS.ai into its manufacturing workflows, this company is not only boosting productivity but also empowering planners with intelligent tools to make faster, more informed decisions—ultimately improving service and profitability.

-

-

Manufacturing Planning: A global industrial materials manufacturer is leveraging IFS.ai to increase agility, streamline operations, and prepare for future growth. Operating across six countries and supplying advanced wire-based products to sectors like automotive, medical, and construction, the company faced complex challenges—aging systems, changing market demands, and the need for smarter resource planning.

To meet these challenges, the company adopted IFS Cloud and is now deploying AI-powered Demand Planning and Manufacturing Scheduling & Optimization (MSO) capabilities with the goal of boosting production efficiency by up to 50%.

IFS.ai addresses core operational problems:

-

Manual and fragmented planning: Replaces siloed, manual demand planning with AI-driven forecasting across global sites, reducing safety stock and freeing up working capital.

-

Inefficient scheduling: Enables real-time, data-informed production scheduling using “what-if” simulations to better utilize resources and meet fluctuating customer demand.

-

Limited visibility across sites: Unifies planning and operational data across regions, enabling synchronized procurement, scheduling, and inventory control.

-

Reactive maintenance: AI insights help predict equipment failures and optimize maintenance intervals, minimizing downtime and material waste.

-

Rigid legacy systems: Transitioning from 30-year-old systems to an AI-enhanced ERP supports digital transformation, mobile workforce enablement, and real-time shop floor integration.

-

Compliance and traceability: IFS Cloud provides full traceability for regulated materials, helping meet strict quality and sustainability standards across supply chains.

With these AI-driven capabilities, the company is not only transforming how it plans and produces, but also positioning itself for future readiness—whether adapting to electrification trends in automotive or entering entirely new product markets.

-

-

IoT Platform Optimization: A global environmental services provider specializing in pest control, property inspections, and hygiene services is using IFS.ai to overcome operational challenges posed by rapid growth, fragmented IT systems, and increasingly strict environmental regulations. Operating in over a dozen countries with thousands of field technicians, the company needed a scalable solution to improve service efficiency and sustainability.

To meet these demands, it deployed IFS.ai and IoT-driven solutions integrated with IFS Cloud to power smarter field operations.

IFS.ai addresses key challenges in service delivery and scalability:

-

Inefficient field operations: AI-powered route planning and scheduling ensure technicians know exactly where to go and when, eliminating unnecessary travel and improving customer response times.

-

Manual trap monitoring: IoT-connected traps automatically report activity and battery status, reducing technician visits and enabling predictive maintenance of devices in the field.

-

Environmental compliance pressures: AI-supported preventive systems reduce reliance on harmful pesticides, aligning operations with regulatory and customer sustainability expectations.

-

Fragmented systems: IFS.ai provides a centralized platform capable of scaling across business units and geographies, supporting acquisitions and rapid expansion.

-

Data-driven decision-making: Real-time analysis of sensor and operational data helps optimize resource use, reduce waste, and extend the life of IoT assets.

With IFS.ai and the IFS IoT Business Connector, this service provider has gained real-time visibility, improved technician productivity, and accelerated its transformation into a proactive, digital-first operation.

-

-

Automated Production: A flexible packaging manufacturer serving the global food and beverage industry turned to IFS.ai to address the complex challenges of rapid growth, rising customer demand, and the need for scalable, efficient operations. With production sites in multiple countries and an expanding workforce, the company needed a solution that could grow with them—without compromising quality or responsiveness.

IFS.ai delivers solutions to key business challenges:

-

Explosive growth management: As the company doubled its workforce and built new facilities, IFS.ai scaled seamlessly, supporting new operations without system disruption.

-

Manufacturing visibility: Real-time production data and available-to-promise functionality allow the business to confidently meet aggressive delivery timelines.

-

Lot traceability and compliance: IFS.ai enabled a switch to a shop-order system that drastically improved traceability, meeting strict customer requirements.

-

Time savings through mobility: With IFS.ai accessible on Microsoft Surface tablets, supervisors, warehouse staff, and production teams gained instant access to critical data—boosting productivity and saving hours of manual effort weekly.

-

Modular, evolving ERP: IFS’s modular structure allows the company to adapt and add new capabilities—like quality control, CRM, and sales tools—as needs evolve.

-

Unified data and document management: Electronic document handling and version control have streamlined operations and reduced administrative overhead.

By combining IFS.ai with mobile technology, this packaging manufacturer has created a highly agile, responsive, and data-driven operation—perfectly positioned to sustain its growth trajectory while maintaining quality and customer satisfaction.

-

Source: https://www.ifs.com/

IFS.ai empowers organizations to break down data silos, transforming raw data into actionable insights with advanced analytics and machine learning. This empowers teams with AI-driven insights for informed decision-making, while contributing to sustainability goals by helping businesses monitor energy use, optimize resource consumption, and support circular manufacturing processes.

Source: https://www.ifs.com/ai

Novacura: Complementing and Expanding IFS.ai with Low-Code Agility

At Novacura, we recognize the immense potential of AI and view it as a strategic theme, aiming to make it an affordable and daily companion for our customers. We understand that while IFS.ai provides a robust foundation for industrial AI, there’s always room to extend and tailor these capabilities to unique business processes. This is where Novacura Flow, our powerful low-code platform, comes into play.

Novacura Flow is designed to complement and expand upon the capabilities of IFS.ai by providing the flexibility to build custom applications and integrations rapidly. Our approach to AI within Novacura Flow focuses on three key areas:

-

Flow Developer Co-pilot: We envision AI assisting developers in building applications more efficiently. This includes capabilities like generating Flow scripts from natural language, preparing import scripts, designing user interfaces, and assisting with ERP API integration. Our developer co-pilot is currently under development as part of Flow Studio.

-

End-User Co-pilot: AI can guide end-users through processes, automate steps, offer interactive help, suggest values for form completion, and assist with data imports and master data configuration. This streamlines user interactions and enhances productivity, making complex tasks simpler for company workers to operate.

-

Process Optimization Co-pilot: By consuming telemetry data, AI can detect anomalies and identify bottlenecks in processes, offering insights for time-step analysis, loop analysis, global data consistency checks, and anomaly/fraud detection.

Furthermore, Novacura has already embedded AI-based automations into our existing applications, such as invoice recognition, receipt analysis, and computer vision object detection. This demonstrates our commitment to practical AI integration that delivers tangible value.

HOW AI ACTUALLY WORKS IN ERP

See 3 Real-Life Use Cases That Deliver ROI: Session recording from IFS Connect North America 2025

• Master Data Cleansing: See how AI boosts data accuracy by up to 80%, streamlining operations and decision-making.

• AI-Powered Sales Forecasting: Learn how one company uses historical propane usage data to predict future demand.

• Machinery Problem Prediction: Discover how AI + OPC-UA integration helps detect equipment issues early—reducing downtime in critical mining operations.

The Synergistic Advantage: Unlocking Greater ERP Potential

By combining IFS.ai’s embedded intelligence with Novacura Flow’s low-code capabilities, businesses can achieve unparalleled agility and innovation. IFS.ai provides the core AI-driven functionalities for optimizing your ERP system, while Novacura Flow empowers you to:

-

Rapidly Extend Functionality: Develop custom applications that leverage IFS.ai’s data and insights, tailored to your specific workflows without extensive coding.

-

Automate Unique Processes: Create bespoke automations that integrate seamlessly with IFS.ai, addressing niche business requirements that might not be covered by standard features.

-

Enhance User Experience: Build intuitive interfaces and AI-assisted workflows that further simplify interactions with your ERP system, making operations more efficient and accessible for all users.

-

Drive Continuous Improvement: Utilize Novacura Flow’s flexibility to quickly adapt and evolve your solutions as your business needs and AI capabilities mature, ensuring your ERP remains cutting-edge.

In essence, Novacura acts as the ideal partner to unlock the full potential of IFS.ai. Our deep understanding of ERP systems and our expertise in low-code development, combined with our strategic vision for AI, enable IFS clients to not only embrace the future of intelligent ERP but also to shape it according to their unique operational demands.

Summary: Your Path to an Expanded, Intelligent ERP

The integration of IFS.ai and Novacura Flow represents a significant leap forward for ERP clients. IFS.ai enriches the IFS Cloud platform with powerful, embedded AI capabilities, offering intelligent decision-making, enhanced efficiency, and industry-specific solutions through features like the IFS.ai Copilot and predictive analytics. Critically, IFS.ai is designed for ease of implementation and operation, making advanced AI accessible to all company workers. Novacura, with its low-code Novacura Flow platform, seamlessly complements this by enabling businesses to extend, customize, and automate processes with unparalleled agility, further simplifying complex integrations and enhancing user experiences. Together, IFS.ai and Novacura empower organizations to achieve new levels of productivity, innovation, and adaptability, ensuring they can harness the full power of AI within their ERP ecosystem and expand their capabilities beyond standard functionalities.