Manufacturing ERP Upgrade: Successful IFS Implementation

In a dynamic business environment, the Polish branch of a Swedish company Nolato (a developer and manufacturer of products in polymer materials) faced operational inefficiencies due to outdated systems and manual processes. With the decision to implement IFS as their ERP system, the team aimed to enhance efficiency and streamline operations. This case study illustrates the challenges encountered, the solutions devised, and the overall impact of the ERP implementation, drawing insights from Novacura’s team members Andrzej Sałęga-Starzecki, Adam Szlembarski, Dorota Kopacka, and Patrycja Kowalska, who were responsible for the implementation. Additionally, notes from the customer side are included to provide deeper context and for the presented material. BACKGROUND: THE COMPANY AND ITS CHALLENGES The Polish branch of Nolato was facing challenges due to reliance on outdated methodologies, primarily using local legacy systems, Excel sheets, and manual processes. Recognizing the pressing need for modernization, they decided in 2022 to move forward with an IFS ERP implementation. Due to corporate requirements, the group implemented version 9 of the IFS system, with plans to upgrade to IFS Cloud in the future. The execution of this ERP system modernization was complex, requiring strategic planning and specialized expertise. Initial attempts to implement IFS in 2022 were unsuccessful, leading Nolato to engage Novacura as their IFS implementation partner. Key challenges included: Assembling a capable team familiar with IFS 9, suited to the specific needs of the Polish division. Configuring essential features like tax compliance and local reporting standards, requiring support from experienced consultants. Addressing compatibility issues between IFS 9 and the company’s manual processes, which relied heavily on physical records. With guidance from Novacura’s team in Stargard, Nolato successfully completed the project, setting the stage for future IFS upgrades and migrations. PROBLEM ANALYSIS AND PROPOSED SOLUTIONS The project kicked off in the second half of 2023, with the goal of completing it by year-end (the go-live phase occurred in June 2024). At the beginning, the project encountered a few problems, such as accessing an IFS support team proficient in IFS9, which was no longer supported by IFS, and correcting the previous Polish extension to IFS. Nolato had already tried to implement IFS in 2022 without major success. A significant challenge during the implementation process was also a data migration from an outdated, local database developed by a Szczecin-based company. The opening balance and initial data import were not problematic; however, preparing the data for migration proved to be more complex. The previous database used different terminologies, which required extensive training and clarification for the clients to understand the new IFS system’s requirements. Our consultancy team worked with Nolato, guiding them through the necessary adjustments. Adam Szlembarski Lead Business Systems Consultant at Novacura This hands-on approach ensured that the client’s team was well-equipped to handle the transition, which was also confirmed by the positive feedback from the Nolato side: The implementation process took place in a very friendly atmosphere. The consultants were always well-prepared and supportive. We tackled the assigned tasks gradually, which often required a great deal of flexibility on Novacura’s part. […]

learn more

Transforming from Merit Portal to Novacura Flow – SMD Logistics customer case

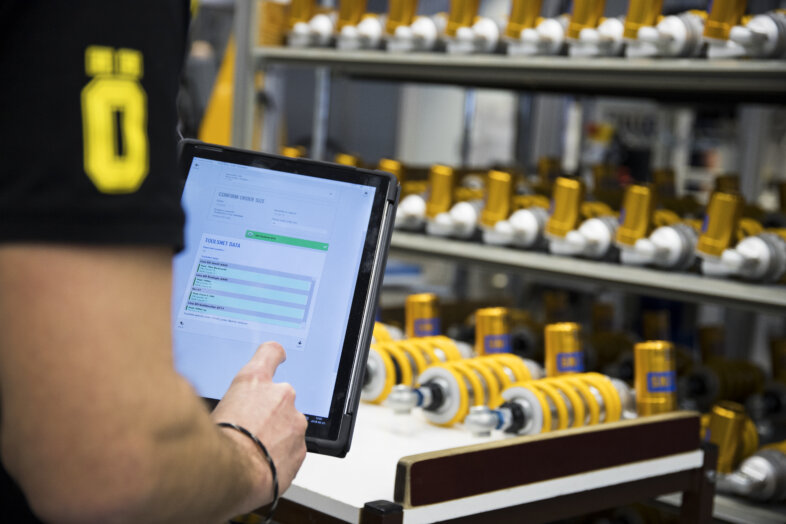

We had the pleasure of speaking with Herman Moodysson, Manager IT & Business Development at SMD Logistics, about their transition from the Merit Portal to Novacura Flow. SMD Logistics serves as the essential intermediary connecting manufacturers with the Swedish market by distributing tobacco and tobacco-related items. Beyond tobacco, they also act as wholesalers for various high-demand consumer goods. SMD Logistics’ distribution infrastructure, guided by principles of security, quality, and sustainability, extends to 10,000 clients across Sweden and Norway. In the interview presented to our readers, Herman Moodysson, IT Manager at SMD Logistics, shared insights into their transition from Merit Portal to Novacura Flow for logistics operations. HIGHLIGHTS FROM THE INTERVIEW The interview was performed on 2024-05-21, between: Herman Moodysson (HM) from SMD Logistics, and Łukasz Majer (LM), Business Solutions & Marketing Director at Novacura. LM: Could you please introduce yourself, detailing your current role within your company and sharing some background information about yourself? HM: Certainly. I’m employed as the IT Manager and Business Development professional at SMD Logistics. I’ve dedicated 13 years of service to the company, with my responsibilities centered around IT since the beginning. Earlier in my career I served as an IT Consultant at Intentia, a company now under Infor’s ownership, where I gained extensive experience with Infor M3. LM: Could you provide us with an overview of your company, including the products/services offered, and target markets? HM: SMD Logistics specializes in the transportation of high-value goods, predominantly tobacco products. We are the logistics partner for all major tobacco companies in the Swedish market and to some extent in Norway. While we maintain our own fleet for the Greater Stockholm area, we rely on external transport companies for other regions. LM: Could you share some key figures regarding your company’s operations? HM: We currently have a workforce of over 200 employees. Our main business is distribution of tobacco products and we serve the majority of retail outlets in Sweden, around 80% directly to point-of sale (POS) and the remaining 20% through wholesale operations. Our clientele encompasses approximately 7 500 delivery points, including prominent chains such as ICA, Axfood, Reitan and Circle K, alongside independent retailers. We also have a small but growing business acting as 3PL to e-commerce customers. LM: Could you tell us something about what differentiates your business from the generic logistics operators? HM: One thing is that we are acting as a logistics partner to different competing businesses, meaning competitive neutrality is fundamental to us. Secondly, since we deliver tobacco products, our business must meet restrictive safety and compliance regulations. LM: Thank you! Could you now provide an overview of your IT infrastructure, including the ERP system you use? HM: As our main ERP system, we use Infor M3 13.4, on-premises. It is supplemented by MEC (M3 Enterprise Collaborator) engine for integration management. Since our strategy is to be a fully digital company, we use several systems to be able to process 98% of our customer orders digitally. We use an EDI platform and we also […]

learn more

IFS Cloud Implementation for Söderenergi – Streamlining Energy Operations

Introduction Söderenergi is a leading energy company, producing district heating and electricity in the Stockholm region, and contributing to the ongoing green transition. We are delighted to announce that Novacura has been chosen as the implementation partner for IFS Cloud at Söderenergi in Sweden. As a Channel Partner for IFS, one of the leading global ERP providers, Novacura’s experts will initially implement the following modules of IFS Cloud: Finance Purchasing Inventory Management The IFS Cloud implementation project commenced in November 2023, with the go-live scheduled for June 2024. Learn more about IFS Cloud Finance Module Novacura is presently in the analysis stage, examining customer needs and requirements. This ERP system implementation will support Söderenergi in streamlining operations and enhancing efficiency, contributing to their digital transformation in the energy sector. Leveraging ERP for energy companies like Söderenergi ensures optimized processes, from finance management to inventory management in the energy industry, helping drive sustainable growth. About Söderenergi Söderenergi generates district heating for approximately 300,000 residents, offices, and industries in the Stockholm region, supplying electricity to 100,000 households. Annually, the company transforms 1 million tons of waste into energy. Learn more about Söderenergi About Novacura As a Channel Partner to IFS since 2018, Novacura offers a comprehensive range of services for IFS, including IFS implementation, upgrades, enhancements, integration, training, and audits. Additionally, Novacura provides a low-code platform, Novacura Flow, enhancing flexibility of IFS platform with low-code solutions for ERP customization. Novacura is honored as a Gold Channel Partner in the Nordics, receiving the prestigious “Channel Partner Awards” three times consecutively in 2017, 2019, and 2022. As a trusted Novacura IFS Cloud partner, the company continues to deliver ERP implementation best practices across industries. Discover Novacura’s IFS services About IFS Cloud

learn more

ERP System Upgrade in the Paper Industry: Nordic Paper’s Migration to IFS Cloud

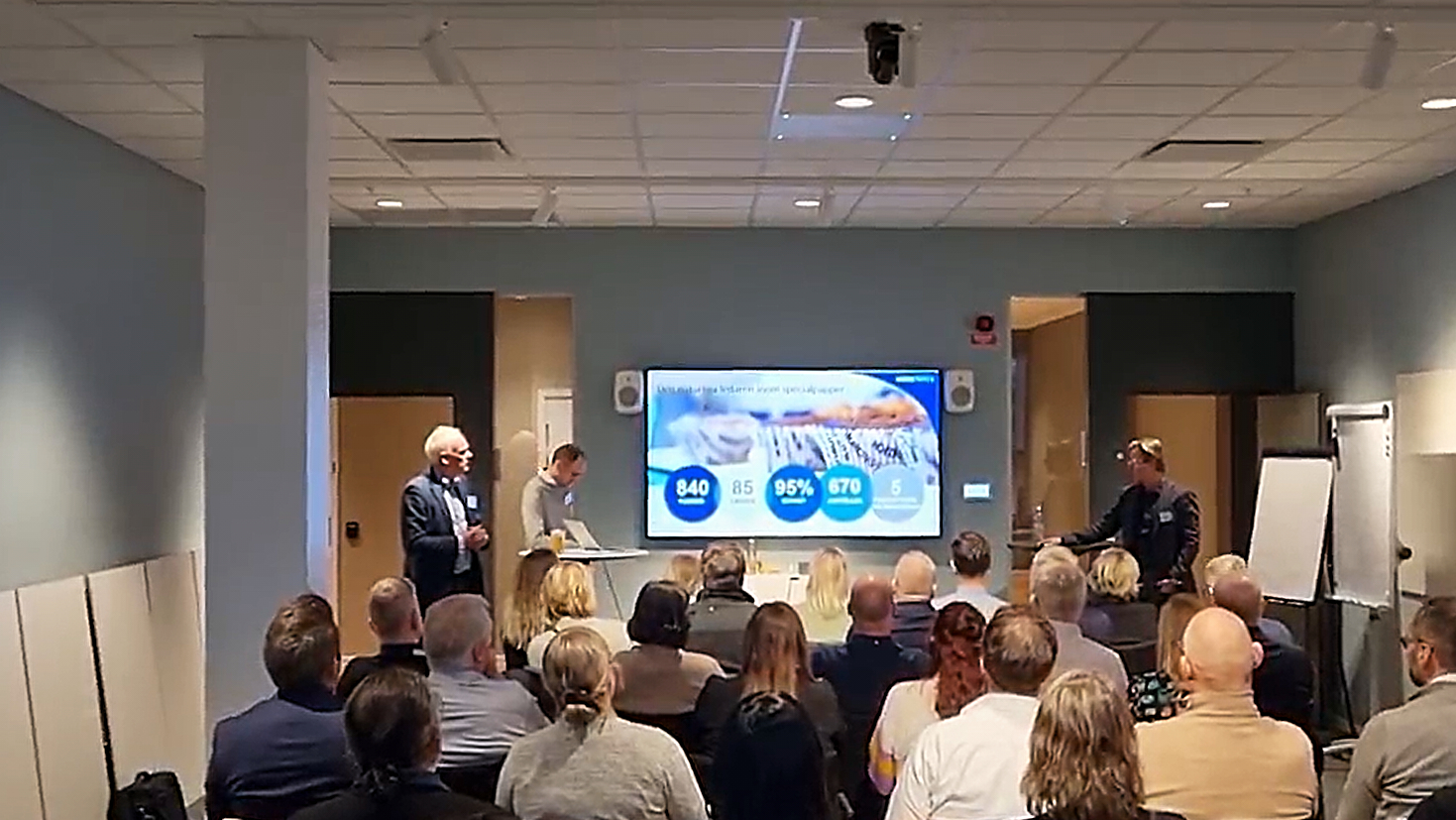

INTRODUCTION Novacura, as an active member of the IFS Scandinavian User Group, lead a seminary during the latest IFS User Group Day on November 22, 2023, in Stockholm, Sweden. Collaborating with our client, Nordic Paper, a leading producer of Greaseproof Paper and Kraft Paper, we had the opportunity to present a customer case centered around the transition process from IFS Applications v7.5 to IFS Cloud, a transition we jointly planned and executed. In the seminar, our speakers — Patric Johansson (CIO at Nordic Paper), Johan Magnusson (ERP Lead at Nordic Paper), and Lars Steen (VP Services at Novacura) — discussed the expectations and insights derived from upgrading from IFS Applications v7.5 to IFS Cloud. Additionally, the session explored IT strategy development, best practices for user training, and how process visualization can drive a smoother transition. Through maintenance management and system support, Novacura ensures that companies like Nordic Paper achieve an optimized and future-ready IFS Cloud implementation. OUR PRESENTATION SUMMARY: “JOURNEY TO IFS CLOUD” During the event Novacura, in partnership with Nordic Paper, provided insights into the migration journey from IFS Applications v7.5 to IFS Cloud. The session featured an open discussion on project experiences, highlighting both accomplishments and challenges in IT system implementation and ERP system upgrade. Presenters explained that the migration process timeframe was between January 2022 and November 2022, and was organized into six phases, which included: Initiation Confirmation Establishment Implementation Go live Support At the conclusion of the presentation, the Novacura experts emphasized that post-live, in an Evergreen state, the overall stability of IFS Cloud was very good. IFS Cloud is a evergreen cloud-based solution offering advanced features tailored to address specific business needs. It follows a systematic development schedule, with releases occurring twice a year at six-month intervals, identified by versions R1 and R2. (The slide from the event presentation). Below, we outline key observations from the successful IFS Cloud upgrade project as presented by the speakers: The slide from the event presentation. WHAT TO EXPECT FROM AN IFS CLOUD PROJECT? The important part of the presentation was a comparison between the recent IFS Cloud Upgrade project and the classical IFS upgrade implementation known from earlier versions of IFS Applications. They underscored the following similarities and differences: The slide from the event presentation. At the presentation’s end, the speakers shared key lessons learned from the project, focusing on technical perspectives. They emphasized the following: Integration with Rest OData can consume more time; New opportunities with Lobbies & Projections may cause Performance issues; Sizing of Middleware; There is no (easy) possibility to roll-back to the previous release when software defects appear; Environments can become desynchronized – proper environment management is necessary. SUMMARY Novacura led a seminar at the recent IFS Scandinavian User Group Day on November 22, 2023, in Stockholm, Sweden. The event received widespread acclaim, generating positive feedback and attracting great interest and interaction from various participants. Jointly with Nordic Paper, a key producer of Greaseproof Paper and Kraft Paper, Novacura presented a compelling customer case on transitioning from IFS Applications v7.5 to IFS […]

learn more

IFS Cloud Migration Best Practices: Mistras Group’s Journey with Novacura Flow

On June 13-14, Novacura participated in the latest edition of the IFS Connect conference organized in North America in Minneapolis, USA. Novacura, as a long-time IFS partner and gold sponsor of the event, had the opportunity to lead one presentation with Mistras (...)

learn more

Mobile approach to Warehouse Processes in Paint Manufacturing in Teknos

Manufacturing and logistics are closely interrelated on many levels. In a modern enterprise, attention is always on productivity and efficiency. Manufacturers have become very cognizant of the importance of measurement and obtaining data from different processes to create a holistic view of the entire business’s effectiveness. Improvements on the shop floor are the essential, but optimizations on the logistics and distribution side are required to accelerate maximum production cycle results. Smart internal logistics and inventory management are deeply integrated into production processes and are essential for efficient total process management (TPM). Focus on business improvement Most manufacturing companies these days are facing some serious problems that are crossing production and inventory management operations. It is crucial for these companies to correctly understand the root causes of the existing issues to clarify the requirements for improvement. Warehouse operations – inefficiencies in connecting the complexity of warehouse operations (order picking, inbound and outbound, inventory management) with the production floor can result in significant financial losses due to faulty packaging management, lack of good coordination of raw materials, utilization of scrap or damage detection. Modification problems – difficulties with modifications that are required to meet new business needs. The old software systems installed on the shop floor need to be more flexible to extend the business capabilities that are needed to manage day-to-day operations. Business solutions from Novacura Problems in operations with manufacturing and warehouse management can be solved with software solutions that can extend the capabilities of ERP systems with mobile and desktop applications. The most appropriate approach is using a solution that will not make changes to the structure of the ERP system itself but will connect independently on top of it and provide the user with the ability to implement continuous modifications whenever required by the business. Novacura Flow is an example of flexible software that can be connected to an ERP system and allow the user to modify a business process at any time. This approach will enable users to respond effectively to ongoing changes driven by production and warehouse operational needs. https://www.novacura.com/wp-content/uploads/2022/08/nc-www-app-creation-in-flow.mp4 The example presented above explains how users can use Novacura Flow, with access to Novacura Flow Studio, environment for developing applications for internal operational needs in warehouses. The warehouse solution for Teknos TEKNOS GROUP OY. is one of the global coatings company from Finland that offers a wide range of paints and coatings for the manufacturing industry, building professionals, and consumers. The company operates in 20 countries in Europe, Asia, and the US, with more than 1500 employees globally. They have achieved outstanding results with their business approach and development in industry-driven product quality. TEKNOS GROUP OY. selected Novacura Flow software in early 2022. Since then, the company has begun implementing Novacura solutions for warehouse operations, which are required in their manufacturing processes. Novacura had the opportunity to speak with Peter Muhonen, ICT Manager, Supply Chain – and RnD Solutions, about recent developments. Improving the warehouse operations Before implementing Novacura Flow, Teknos already used the Novacura service to connect its IFS ERP […]

learn more

8 min to read

8 min to read