3 min to read

3 min to read With technology advancing at breakneck speed, manufacturers are constantly striving to modernize and remain competitive. For Vedum Kök & Bad, a leading Swedish manufacturer of kitchens and bathrooms, this meant moving beyond legacy systems to embrace a flexible, low-code platform. This case study explores Vedum’s successful journey with Novacura Flow, which led to improved efficiency, real-time data access, and a new era of self-sufficiency.

CUSTOMER BACKGROUND

Founded in 1919, Vedum Kök & Bad is a family-owned company with a strong, long-term vision. They are a leading producer of kitchens, bathrooms, and storage solutions in Sweden and Norway, with all their production taking place at their factory in Vedum, Sweden. With approximately 320 employees and a focus on caring for their people and partners, Vedum maintains a robust company culture.

The Challenge of Outdated Systems

Vedum’s main obstacle was their outdated production and ERP landscape. They had recently upgraded their ERP to M3 Cloud, a major project since the previous system dated back to 2001. However, their two legacy production systems, “Extend” for warehouse operations and “Vedprod” for manufacturing reporting, were inefficient and lacked real-time data integration. This fragmentation of information led to challenges in tracking production status and making quick, data-driven decisions.

Standard approach to working with ERP

Exploring Solutions: Why Novacura Flow

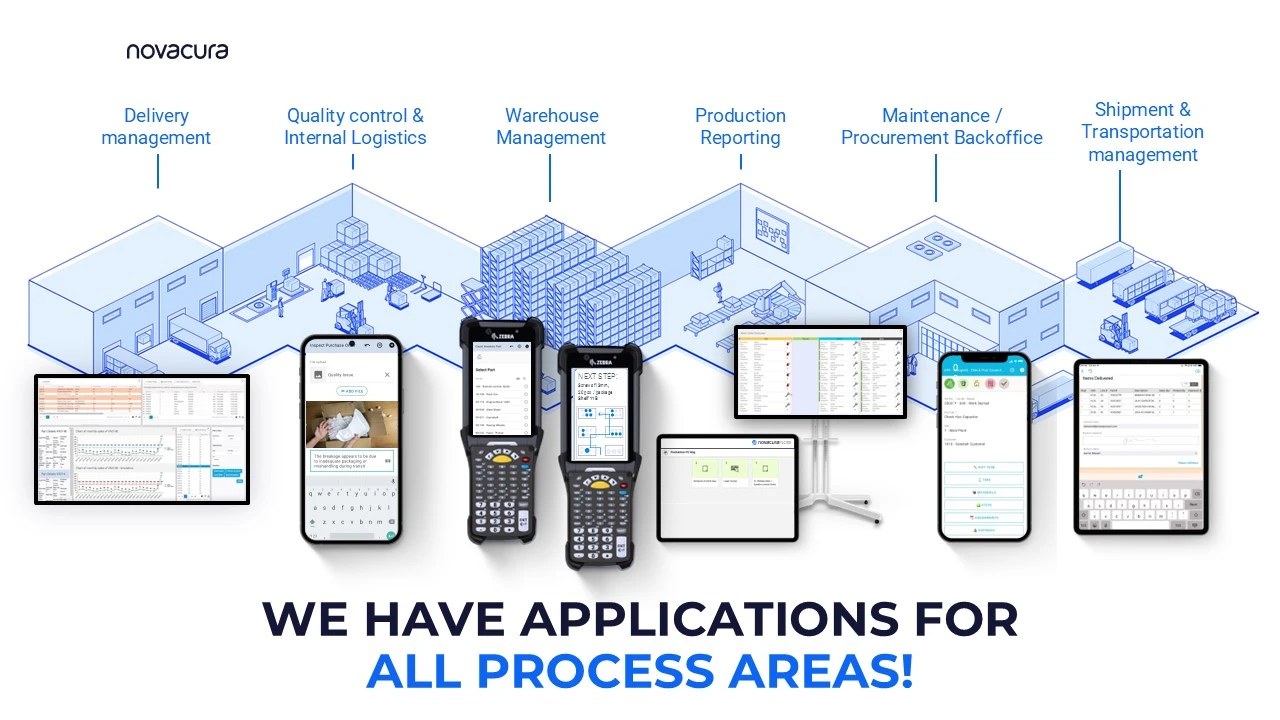

To address these issues, Vedum decided to implement Novacura Flow. They were drawn to the low-code platform for its user-friendliness, web-based nature, and extensive library of ready-to-use applications. Novacura Flow provided a powerful “window” into their ERP, allowing them to pull real-time data via APIs. The platform enabled Vedum to replace their old production systems with modern applications that provide real-time reporting at every stage of the production process.

Enhanced Production Reporting with Novacura Flow

Implementation Journey: From Legacy to Low-Code

The transition to Novacura Flow has empowered Vedum’s team to become more innovative and self-sufficient. The low-code functionality has made it easy for them to develop and modify applications on their own, significantly reducing their reliance on external consultants. The new system has improved inventory control and provided better production planning and statistics through high-quality, real-time data.

In a demonstration featured in the provided video, Markus Eriksson from Vedum showcased a new application he built in Novacura to manage and plan for missing components. The app visually tracks production orders for missing parts and highlights how easily solutions can be developed in Novacura Studio without extensive programming knowledge.

Conclusion: Foundations for Continuous Improvement

Vedum’s experience highlights how Novacura Flow can be a perfect tool to address key areas of business transformation: mobility, process automation, and integration. By leveraging the platform’s low-code technology, Vedum has not only overcome the challenges of its legacy systems but has also laid a foundation for continuous improvement and innovation.

Watch how Frans Stridh and Markus Eriksson from Vedum, together with Christian Natt Och Dag and Robin Huizer from Novacura, shared the story of “The Transition to Novacura Flow – A 2-3 Year Journey” at the Working Together Conference 2025 in Linköping, Sweden. Discover how their step-by-step transformation streamlined processes, enhanced flexibility, and delivered long-term business value.